OAL News

OAL to build new APRIL™ Robotics production facility

We’re very pleased to announce the development of our new state-of-the-art facility to support our APRIL™ Robotics Systems in Cambridgeshire, UK. The new facility supports a growing order book as food manufacturers seek to avoid rising costs in the UK and Europe through significant productivity improvements.

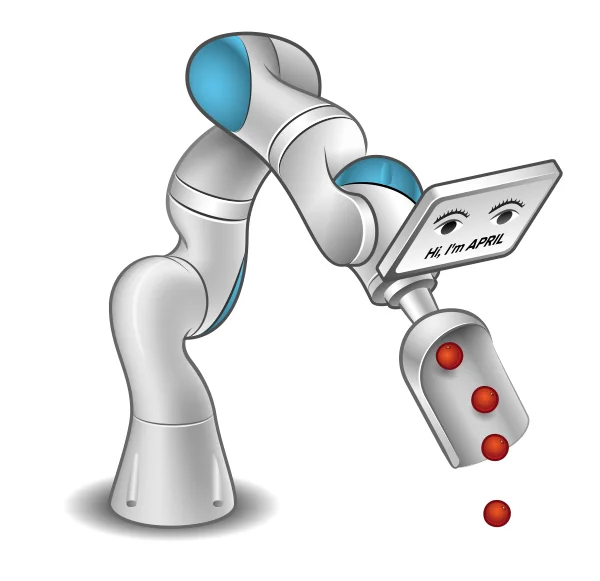

Currently, 529,800 people globally are associated with the common repetitive task of weighing dry ‘micro’ ingredients. The APRIL Robotics Ingredient Handling system automates this task and when linked with APRIL Logistics, fully automates the ingredient and material management within factories.

The OAL team is rapidly accelerating the adoption of robots in food manufacturing as they focus on increasing productivity and efficiency in food factories by automating manual handling tasks. Harry Norman, Owner/Managing Director at OAL, explains more:

“We’re committed to eliminating manual handling in the front end of food processing, and the new APRIL facility gives our team a great space to develop and demonstrate what that means for food manufacturers.

We have a strong reputation for building large scale material handling projects, and advanced manufacturing software (OAL Connected) and the APRIL developments complement these thriving parts of the business.”

So if you’re ready to bring robots into your facility, arrange a visit to learn more about APRIL Robotics today.

OAL secures £450k funding for robotics in food manufacturing

We’re delighted to announce that we have been awarded £448,850 to develop innovative APRIL™ robotics material handling systems for food manufacturers from Innovate UK, the UK's innovation agency. The new project focuses on overcoming the well-documented productivity challenges food manufacturers face preparing ingredients. It will be led by engineers from OAL utilising the latest robotic and automation technologies.

The new one-year project, which is supported by a grant of £448,850 from the UK Government via Innovate UK and the EPSRC's Robotics and Autonomous Systems (RAS) research fund, will focus on automating the processes of handling, weighing and transporting the raw ingredients. It will also make strides in developing key hygiene and food safety features which will be crucial when using robotic production systems within the food manufacturing sector. Researchers from the University of Lincoln will be supporting the project with work being undertaken at the National Centre for Food Manufacturing, Holbeach, UK.

“Food manufacturers are facing rising costs and with little opportunity to increase their prices, they are seeking new and effective ways of improving productivity. Throughout the project, we’ll be taking a step-by-step approach, working our way through common operations found across the food manufacturing sector such as weighing, sieving, and moving ingredients around.

One criticism of automated systems in the past has been the lack of flexibility, but we will aim to develop flexible APRIL robotic systems that can handle some of these tasks and take the pressure off food manufacturers.”

Take the first step towards the robotic revolution with us - get in touch today.

APRIL™ shortlisted for Best Technology Innovation at the World Food Innovation Awards 2017

APRIL pouring water

We’re pleased to announce that our APRIL™ Robot Chef has been shortlisted for the World Food Innovation Awards 2017 in the category ‘Best Technology Innovation’. The esteemed judging panel, including the Global Sustainability Director for Mars, recognised the transformative impact robotics will have on making food manufacturing more consistent and flexible. The winner will be announced on Monday 20th March as part of the International Food and Drink Event (IFE), ExCel London. Click here to see the full list of finalists.

UK food manufacturing faces a number of significant challenges over the coming years, not least the impact Brexit will have on the availability of labour. Sticking with same old, labour-intensive processing and material handling technologies will become cost prohibitive and leave manufacturers unable to fulfil the wide range of products retailers and consumers have come to expect.

APRIL (Automated-Processing-Robotic-Ingredients-Loading) developed with the University of Lincoln, reimagines the food production line, placing robots at the heart of the way we handle and process raw ingredients. By combining advanced materials handling and processing technologies, APRIL can consistently emulate how chefs cook in a professional kitchen bringing more restaurant quality food to our supermarket shelves.

“We are excited by the new thinking involved in the APRIL robotic chef approach. Modular robotics cells may transform food manufacturing kitchens, by breaking up processes in a different way, in doing so providing a step change in performance.”

For manufacturers, smart, robotic food production lines will simplify the way we manufacture products offering flexible consistency. Factories will become up to 80% smaller and the increased levels of control will lead to a safer operating environment and improvements in product shelf-life.

The winner of this award will be announced on Monday 20th March at the International Food and Drink Event at the ExCel in London.

Robotics & Food Manufacturing 4.0. Are you ready?

Whether robots really belong in a food factory is becoming a no-brainer. In order for the food industry to improve and grow, robotics and automation WILL play a major role in the food manufacturing process. Andrea Paoli reveals how robots have taken root so far in our manufacturing systems and are set to revolutionise the food industry in Food Manufacturing 4.0 and beyond.

The value of robotics

Andrea Paoli presented a number of very enlightening figures when introducing the impact robotics will have in the future. Here are a few to set the scene:

The Bank of England in November 2015 predicted that over the next decade, 15 million jobs will be taken over by robots.

In 2020, the robot market is expected to hit a value over $83 thousand million.

It’s predicted that the global saving for using robotics in terms of labour cost is 16%.

By increasing investment in automation by £1.2 billion, this could raise the overall value added by the manufacturing sector to the UK economy by £60.5 billion. This could safeguard 106,000 jobs.

Since the industrial revolution, robots have gone from mechanical production equipment driven by water and steam all the way to cyber-physical systems which integrate computers, networking and physical processes. The degree of complexity of robotics is forever increasing. As you can see from the videos in Andrea's slides, the capabilities of robotics and automation have increased and improved dramatically. Is there anything they won’t be able to do?

So what does Food Manufacturing 4.0 look like?

Robotics and automation have progressed in such a way that it’s safe for them to work in collaboration with humans (HRC systems - Human/Robot Collaborative systems). They can work to full capacity 24/7 producing the same results they’re programmed to complete. This is impossible for humans to achieve to the same degree of accuracy and consistency.

Therefore, there is a massive opportunity for an increase in productivity for food manufacturers due to the reduced cycle and turnaround times. A robot can work within stabilised conditions without human interface. Not only does this improve the health and safety of the factory, it can also increase the shelf life of products contributing to reducing waste which is a very hot topic at the moment!

Working together with the University of Lincoln, OAL has been championing Food Manufacturing 4.0 and have developed a robotic chef APRIL. APRIL is facing up to the challenges food production is facing to introduce a flexible, automated, continuous, high volume system to food manufacturers. Read more about APRIL and her talents here.

How will a future food factory look?

A factory of the future will run on big data being used intelligently to improve decision making and planning. Cloud computing will allow for anything to be controlled, recorded or reported in real-time. With humans collaboratively working together with robots along with all the big data that will be available, factories will be able to optimise production, reduce wastage and improve product consistency and quality.

Join OAL on this journey by helping us educate the industry to deliver disruptive change in manufacturing securing your factory’s future as well as the future of the food manufacturing industry.

McKinsey report: where will automation replace humans in food manufacturing

Food service and manufacturing sit at the top of a recent McKinsey report that analysed work activities rather than occupations as a predictor of automation. By identifying jobs with predictable physical work, data processing or data collecting, they were able to assess the technical feasibility of automation. By breaking down jobs by activities, up to 59% of time spent at work in the US is highly susceptible to automation. Further analysis suggested that food service and manufacturing were more suited to automation than others i.e. many activities within food manufacturing are highly susceptible to automation.

Technical feasibility of automation in food

The McKinsey report highlights food manufacturing and food service as highly susceptible to automation due to the activities involved in the jobs (see figure 1). The main driver for this is the high amount of time people spend on predictable physical work. Often in food factories, people will undertake a high number of predictable activities such as lifting product, moving ingredients etc. (see figure 2).

In our experience, the trend fits for our customers who manufacture a smaller range of SKUs and have already been able to automate a high number of the predictable activities. This is in contrast to chilled food manufacturing, where upwards of 40 SKUs can be produced per day and predictable and unpredictable activities become intertwined.

One major part of the puzzle will be splitting out the predictable from the unpredictable physical work, thus enabling higher levels of adoption of robotics. For instance, lifting ingredients into a saucepan is a predictable task but judging the taste of the food requires the expertise of a chef, hence it isn't so susceptible to automation.

We're working with the University of Lincoln to develop robotic systems that provide manufacturers the flexibility to split out the predictable from the unpredictable thus enabling greater levels of automation. APRIL™ the Robot Chef installed at the National Centre for Food Manufacturing enables this flexibility by breaking down activities in a different way to traditional manufacturing processes.

Mckinsey Technical feasibility

Mckinsey industry Feasbility