OAL test centres

OAL has two test centres, to give you access to our full range of processing, robotics and automation technologies. When you visit our test centres, our teams of experts work closely with you to optimise your procedures and evaluate your products, ensuring that our solutions exactly meet your needs. You can visit us at:

National Centre for Food Manufacturing, Holbeach, UK - APRIL Robotics demonstrator including powder weighing and batch making.

OAL test centre, Cambridgeshire, UK. Automation development lab including OAL Connected training and demonstration equipment.

We offer remote demonstrations for those further afield or those unable to travel due to COVID-19 restrictions. We can also loan equipment for onsite testing depending on your needs.

The National Centre for Food Manufacturing (NCFM)

Our 400m² test centre is located at the National Centre for Food Manufacturing, a satellite campus of the University of Lincoln, in the UK. Sitting within academic surroundings, the offsite location is perfect for blue sky thinking and breaking away from your day-to-day operations. Here, you can test out Steam Infusion on your own recipes and processes, spending a day with our team cooking with the technology and exploring new products or evaluating our product matching capabilities. The test system has all available configurations of the Steam Infusion Vaction™ Pump including, In-Tank Steam Infusion, In-Line powder entrainment recirculation and single pass four units in series on a 500kg (1,100lb) test system.

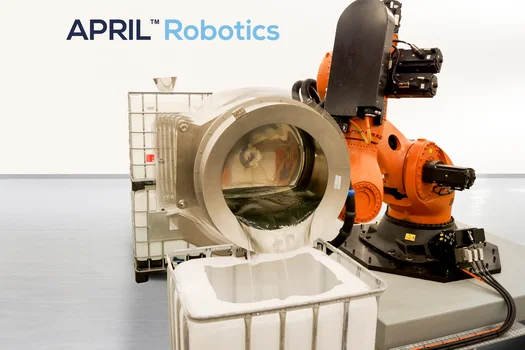

The NCFM is also home of the APRIL Robot Chef, our revolutionary robotic cooking system. With live demos using your ingredients and recipes, you can see for yourself how our robot can cook like a professional chef at an industrial scale. Using our Steam Infusion technology in the cooking module on a KUKA Titan robot, the APRIL Robot Chef fully automates processing operations and achieves major productivity improvements, sub 1% yield losses and extended shelf life, all within a much smaller footprint than traditional equipment.

With our Development Chefs on hand to facilitate and advise on recipe and process changes, it’s amazing what can be accomplished in a single day. You also have access to the university’s full suite of analysis equipment including sensory suite, Mastersizer laser particle size analyser and GC-MS (Gas Chromatography-Mass Spectrometry Analysis) equipment so you can rest assured that you understand the full impact of Steam Infusion and our Robot Chef on your products before committing to purchase.

OAL test centre

Our experts are ready to take you on a tour of our label & date code verification solutions and explain just how you can safeguard your operations while delivering a return on your investment. From the scanners to the PC and the product sensors to the printer connections, with an OAL Connected demo you’ll understand how the system works and why it’s already in use on 1,200 packaging lines!

Our demo equipment can be adapted to better reflect your operations and demonstrate how our solutions prevent a product recall. If you send over a sample of your packaging ahead of your visit, or bring some on the day, we can run it through the system to showcase how we can safeguard your packaging line and protect your business, brand and bottom line.

There’s also the opportunity to experience the latest developments in label and date code verification, including the world’s first artificial intelligence-based solution for label and date code verification, APRIL Eye. Our demo equipment can be adapted to better reflect your operations and demonstrate how we can effectively prevent a product recall. We find that seeing is often believing so if you send over a sample of your packaging ahead of your visit, or bring some on the day, we can run it through the system to showcase how we can safeguard your packaging line and protect your business, brand and bottom line. There’s also the opportunity to undertake superuser training here if you prefer to complete this offsite.