LABEL & PACKAGING VERIFICATION

Stop packaging errors and recalls with AI label verification

OAL’s proven system automates label and date code checks across 2,000+ packaging lines, helping you stay compliant and audit-ready.

Sleeve verification on sausages

Eliminate packaging errors in your food business by verifying each packaging element to the running job.

100% continuous verification of primary/secondary packaging and labels

Reduce rework and downtime from packaging errors

Track allergens with artwork version control using 2D codes

Proven verification solutions for complex packaging operations including:

Aldi, Co-op, Lidl, M&S, Morrison’s, Sainsbury’s, Tesco, Waitrose Code of Practice Compliance

Spinning pots and lid “marriage” (see Heinz case study)

Promo label management

AI Label Verification

Capture an image of every pack and verify every element using APRIL Eye, powered by Cognex.

Verify the content of every label at rates up to 200 packs per minute (ppm) including:

Packaging artwork

Date code, use by or best before

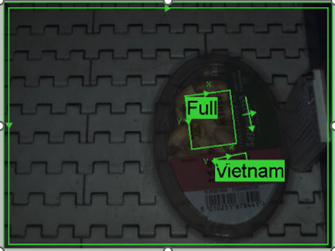

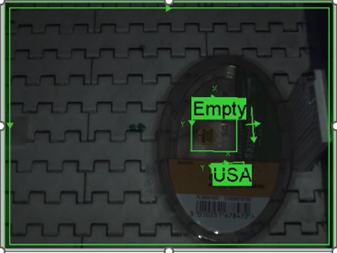

Variable field information, including “Country of Origin” & “Grower”

Promo label presence and content

Finished product (if visible)

Trusted by Leading UK Food Manufacturers

OAL already supports automation and quality assurance across more than 2,000 production lines in the UK food industry.

“Without a doubt I would recommend OAL to other manufacturers […] this system is the failsafe.

Sarah McGeehan

Group Technical Manager, Life Health Foods (M&S Supplier)

“The team at OAL are easy to work with, working together we have implemented a robust automated label and date code verification system. The 24/7 support is quick, friendly, and efficient!”

Fran McNally

Quality Manager, Worldwide Fruit (M&S Supplier)

“I’ve been very impressed with the OAL system, it’s really been a game-changer for us. What was originally brought in to prevent product recalls has now become an invaluable tool to improve our production efficiency.”

James Robertson

Operations Director, Joseph Robertson

Verify printed information, artwork and promo label

Verify artwork text and promo label

Verify country of origin and product

Verify country of origin and presence of product

Verify cherry seal entrapment

Verify salad seal entrapment

Verify every PLU on a tray of avocados

How does the OAL Label Verification System work?

-

Our team will assist you in the quick and easy setup of the OAL Label Verification System tailored to your specific requirements. We’ll help add your products to the Master Product Database so our cameras can verify their labels and packaging.

-

The system can seamlessly integrate with your existing business systems or databases, ensuring a smooth flow of information.

-

Our system uses advanced camera technology with AI to identify labels, cross-referencing them with the designated product information. It verifies barcode data, product codes, expiration dates, and any other critical label elements.

-

Once scanned, the system instantly provides feedback, indicating whether the labels are correct and compliant or if any issues need attention. The system will trigger a line stop for further investigation.

-

You have the flexibility to set up customisable alerts, allowing key personnel to be notified of any label discrepancies or potential concerns.

Inline/Online Packaging and Label Verification

Pot and lid verification on ice cream

Every pack is scanned and verified. A camera is mounted to the line to scan packaging barcodes and verify against the running job.

Multiple barcode cameras are mounted on the line to scan all elements for products with multiple packaging elements (pot, lid, sleeve).

Standard operation

The operator selects the job/product to run on the OAL Line Terminal (touchscreen) from your production plan

The OAL system automatically sets up the cameras for the selected job

A 1D/2D camera will scan and verify the packaging against the running job

If the wrong packaging has been selected, the line will stop and require an investigation

Offline packaging verification

Manage labels printed offline with the OAL system. Verify offline (pre-printed) labels against the live packaging job.

Standard operation

The operator selects the job/product to run on the OAL Line Terminal (touchscreen) from your production plan

The operator is prompted to complete QA checks on job start, including using the hand scanner “hand scanning” to verify the correct labels have been brought to the line for the running job.

Quality checks are undertaken to check the first and last pack and intervals during production (typically 30 minutes)

Protect your packing operations today

Contact us for a demo

+44 1733 394700

A1 Parkway Peterborough, PE2 6YN, United Kingdom

sales@oalgroup.com

Got a question? Call us now on

© Copyright | 2025 OAL Group, LLC