OAL News

OAL 3 Peaks Challenge 2023

We’re hiking the 3 Peaks in June to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

We’re hiking the 3 Peaks to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

In June, a team from OAL will be putting down the tools and stepping away from our keyboards to take on the 3 Peaks Challenge in under 24 hours!

The 3 peaks are made up of Ben Nevis (1,344m), Scafell Pike (978m) and Snowdon (1,085).

We‘re starting on Saturday 23rd June with Ben Nevis, hopping in the van down to hike Scafell Pike, and finishing in the early hours of Sunday morning at the top of Snowdon.

Will it be a software, mechanical, design or electrical engineer to reach the top of Snowdon first?

We’re raising awareness and money for StrongMen, a great local charity that has helped us overcome the mental health challenges of bereavement.

If you would like to donate, you can here: https://www.justgiving.com/fundraising/oal-3peaks

OAL customer support ticket portal

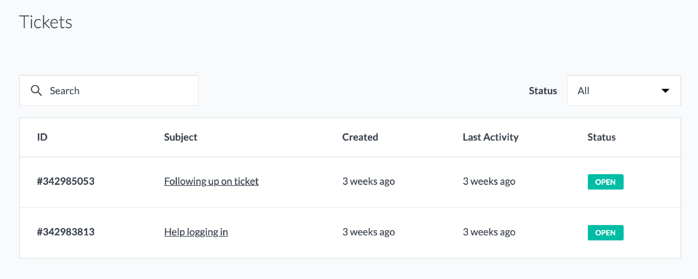

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

Customer Ticket Portal

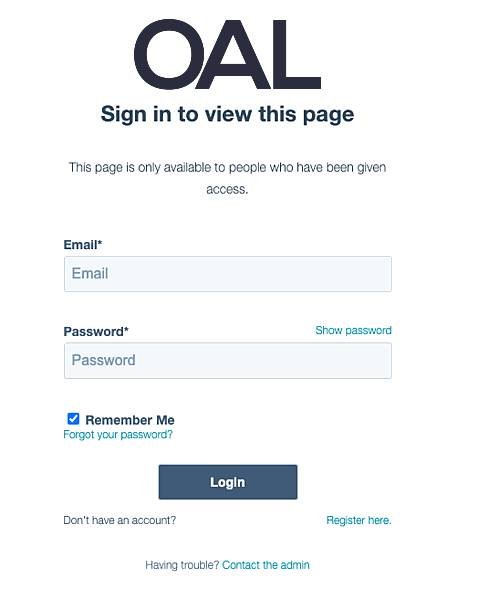

To access the customer portal, please contact OAL and we’ll enable the portal for your account.

You’ll be sent an email to register using your work email address.

Once registered, click here to login to the ticket portal.

The portal provides the following functionality:

User account and login to OAL Customer portal.

Visibility and communication history for all tickets within your organisation.

Ability to raise a ticket.

If you need any assistance or have any feedback, ring +44 1733 394701 or email support@oalgroup.com

10 reasons to work at OAL

We’re always looking for passionate, talented individuals to join our fast-paced innovative company! When searching for a new role, you may ask yourself why would I want to work for them? To help you answer that question, we’ve asked our team and come up with 10 reasons to work at OAL!

We’re always looking for passionate, talented individuals to join our fast-paced innovative company! When searching for a new role, you may ask yourself why would I want to work for them? To help you answer that question, we’ve asked our team and come up with 10 reasons to work at OAL:

1) Diverse customers

“OAL has an incredibly diverse customer base. The opportunities to drive the food industry forward are fantastic. And because we work with customers all over the world, there are great opportunities to travel.”

2) Endless oppportunity

“You get a chance to develop new skills in many engineering disciplines. ”

3) Cutting-edge technology

“It is great to always be working with new technologies that nobody else has access to.”

4) Share great experiences

“Each day provides incredible opportunities to work with both colleagues and customers who are the best in their field.”

5) Management that care

“The MD is so motivated, it’s very contagious. It’s great to work with like-minded people.”

6) Challenging

“In my role, I get to face and solve new challenges every day.”

7) Food is life

“Knowing that we’re helping to improve the way we make food is incredibly rewarding.”

8) Flexible

“OAL has always been understanding and accommodating of my own circumstances and the hours that I can realistically work. They aren’t stuck in the old 9 to 5 age and had adopted working from home policies before COVID-19 made it the norm! ”

9) Teamwork

“At OAL, I get to interact with a very varied friendly group of colleagues. I learn something new from them every day.”

10) Valued

“The business makes me feel welcomed and valued and my manager is always on hand to advise and help.”

So, want to join the team? Visit our careers page to see our latest vacancies. If you’re not sure where you’d fit, feel free to send us your CV and let us know why you want to work with us: jobs@oalgroup.com

Harry Norman's top 4 tips to thrive in 2020

With almost 30 years working with the food industry, Harry Norman’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

During the current climate of uncertainty, it’s clear that food manufacturers are up against it. Having to meet increased demand with fewer people while also implementing social distancing measures to protect staff and at the same time working with equipment that has perhaps seen better days… It’s certainly been a hard few months and it’s likely to continue. As reported in The Times, analysts at Peel Hunt have calculated that £23 billion has been cut from CAPEX budgets for this year in British listed companies alone. This means that it could be some time before manufacturers can consider investing in new machinery, let alone innovations to take operations to the next level.

It’s now more important than ever to make the most of what you have, something that our MD, Harry Norman, knows plenty about. With almost 30 years working with the food industry, he’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

Digital transformation

Productivity has always been the key buzzword in the global economy, but it has perhaps never been more necessary to return to pre-2008 levels. It was reported in February 2020 that the slowdown in productivity growth in the UK over the last ten years is the worst since the start of the Industrial Revolution 250 years ago, and the impact of COVID-19 is likely to have only worsened this situation.

So the question is, how can you increase your productivity, particularly if you can’t invest in major capital equipment? One way is to begin your journey towards digital transformation. By digitising your operations, you can typically achieve productivity savings of 10% running smarter and leaner and making the most of your existing assets. For example, by going paperless, your plant data can be transformed into useful insights, rather than disparate sheets of paper, allowing you to identify bottlenecks, downtime issues and waste. Our experts, trained in Six Sigma, alongside our software such as our LMS or APRIL Eye, can help you drive productivity gains across your entire facility.

Process simplification

Total production time for three 1,000 kg (2204 lb) batches of béchamel sauce using a traditional steam jacketed kettle vs. Steam Infusion.

When was the last time you reviewed your processes? We mean really delved into the detail? Chances are, it’s been a while and you could benefit from a fresh set of eyes highlighting any simplifications or rationalisations that can be made to speed up operations and boost efficiency. OAL is 100% dedicated to the food industry, and having completed hundreds of projects for manufacturers, both big and small, it means our experts can look at things differently, saving our customers millions of pounds through simple changes to improve throughput.

For example, one of the ways in which we can reduce the processing time of a béchamel sauce is by using our award-winning Steam Infusion technology, which not only achieves faster cooking times but also reduces the number of processing stages required. The traditional roux is not needed at the beginning of the process, and Steam Infusion can be used to mix whilst heating, while the lack of burn-on means that the number of CIP cycles can be reduced by up to 80%, saving valuable time and money.

Focus on maintenance

There’s no doubt that as people, we’re all more interested in innovation than maintenance, and it’s no different when it comes to plant equipment. But while budgets are tightened, it will become vital to make the most of your existing kit. It might be tempting to reduce maintenance right now but while you may see short-term gains, you could see long-term damage. An effective maintenance schedule and working with experts can help to take care of your kit to help it last longer.

For example, our Steam Infusion technology can also be used to extend vessel life. There’s no need to condemn your kettle cooking system and invest in a new jacket or tank if it fails the pressure tests or is no longer cooking efficiently. A simple retrofit adding one of our In-Tank Steam Infusion Vaction Pumps breathes new life into your existing kit, while delivering added benefits such as near maintenance-free operation and energy efficiency – particularly valuable at this time.

Consider used equipment

As we see the unfortunate news that some plants are closing due to the challenging economic conditions, we will inevitably see a rise in used kit coming on to the market, and this will be of a better quality that can usually be found. This can often be a cost-effective way to boost your productivity but it can be a challenge to find the right equipment and ensure that it is installed seamlessly into your existing processes.

While used kit can often represent a bargain, it requires a diverse set of engineering resources to integrate equipment that doesn’t meet your exact requirements. It may look great on paper but there are a number of questions to consider, such as how old is it, what is the warranty, are the controls current and even how will you get it to your plant?

Working with trusted partners, such as OAL, who have experience in delivering both new and refurbished equipment, as well as effective maintenance, ensures you get the right advice before committing, allowing you to minimise the risk and maximise savings.

Get in touch today to see how we can support you during this time!

Harry Norman's predictions for 2020

As we gear up for another busy year and the start of a new decade, Harry Norman, our founder, reveals his top trends for 2020.

As we look to the start of a new decade, we’re taking some time to speak with our founder, Harry Norman, to discuss what he thinks are the key trends in 2020.

Harry, what are your top trends for 2020?

I think main focus in the food industry in 2020 is a continued focus on improving productivity. This will be achieved through a variety of initiatives as well as the growth in adoption of tools like robotics and machine learning.

It seems like productivity is a permanent concern for food & beverage manufacturers. How can they make a material difference to their productivity levels in 2020?

Productivity has been a major concern for businesses around the world for over a decade but we don’t seem to be able to find the right answer. Latest figures from the ONS showed that productivity in the UK fell at its fastest annual pace in five years in during the April-to-June quarter of 2019, so arguably the problem is getting worse rather than better. Productivity in the food industry has been dropping due to increased product complexity, which requires more production staff to achieve the same volume. This has also led to further erosion of margin as labour costs continue to increase. In April 2019 the national living wage for those aged 25 and over in the UK increased by 4.9%, from £7.83 to £8.21, and it’s set to rise further. The same trend can be seen across the globe so manufacturers need to think outside the box in terms of their productivity.

We know that this is a real priority for our customers but we find that the solution is often in overlooked areas of manufacturers’ operations and that small savings can really add up. For example, if you’re carrying out offline printing on your packaging line, the time taken for a changeover for a new supplier code can quickly mount up. We’ve been able to save customers typically 1-2% of line manning hours by automating the changeover, allowing them to increase production time and reduce labour costs as fewer personnel are needed on the line. By working with experts to review their operations, food manufacturers can find many examples like this and boost their productivity levels by increasing efficiencies.

Robots are another way for manufacturers to boost their productivity – do you think adoption in the food industry will grow in 2020?

Absolutely! As an industry we have generally been slower to adopt robotics than others such as automotive. But the barriers are starting to be broken down and we’ve already seen growth of 50% in robot adoption over the past five years, primarily due to retailer pressure for larger volumes at lower prices combined with consumer demand for safer and more sustainable production. However, we know that this growth has primarily been driven by robotics on the packaging line. I believe that 2020 will be the year that we achieve significant growth in robotics upstream in the processing stage of food and beverage production.

In 2018, we began to see reference sites piloting our robotics technology, and now as we enter 2020 this technology is really taking off. Food and beverage manufacturers are eager to take advantage of the proven results that APRIL Robotics can bring. Our robot chef and automated ingredient handling system allow manufacturers to move to unmanned production, boosting productivity, cutting labour costs and improving product safety – three priorities for manufacturers all over the world. We’re able to achieve payback within two years on our systems so automation of your processing stages needn’t be a pipe dream!

Closely related to robotics is the trend of machine learning. What do you think the impact of this technology will be on the industry?

Machine learning has the potential to transform the food industry. Many companies in Asia have already adopted AI in their food safety processes and it can be used in all areas of the food industry to aid continuous improvement & process optimisation, forecasting, the speed and accuracy of operations, and of course, productivity. A 2017 study by PWC found that global GDP will be 14% higher by 2030 as a result of AI adoption, which will contribute an additional $15.7 trillion to the global economy.

I believe AI will play an even bigger role in 2020. However, it can be really difficult for food manufacturers to know where to start. At OAL we help manufacturers to incorporate AI into their packaging lines to boost productivity by scanning over 1000 packs per minute inline much more accurately than human operators every could. Our AI-based label & verification systems also allow manufacturers to keep up with changing packaging formats without the need to re-programme the system – saving time and increasing throughputs. And because you have machine vision with a brain, you can switch to unmanned operations, further supporting your bottom line by reducing labour costs, all the while preventing product recalls and reducing waste. It’s a great first step for manufacturers looking to take advantage of the benefits of AI.