100% Seal Integrity Verification

The UK standard for seal integrity verification

Trusted by major retailers, OAL protects more than 2,000 production lines.

Achieve 100% seal integrity verification and eliminate the biggest cause of packaging complaints.

Avoid the risks of leaks, rework, waste and lost retailer confidence with OAL – the proven compliance system trusted by technical teams across the food industry.

100% inline inspection

Eliminates sealing errors and complaints

Integrate quickly with your existing lines

Our system is the benchmark for compliance, trusted by UK retailers

Eliminate Seal Related Complaints in your Food Business

100% continuous seal verification and inspection

Detect product in the seal, weak seals and cosmetic seal defects

Reduce waste, rework and unplanned downtime

Guarantee seal integrity at critical quality control points

Seal failures are one of the biggest causes of packaging complaints and product withdrawals. OAL’s seal verification system removes that risk by checking every seal on every pack, directly on the line.

Bring your own products — we’ll show you live seal verification performance.

Protects over 2,000 food production lines.

“Without a doubt I would recommend OAL to other manufacturers […] this system is the failsafe.”

Sarah McGeehan

Group Technical Manager, Life Health Foods (M&S Supplier)

How seal inspection works?

The OAL system combines intelligent software with robust hardware to automate seal verification and inspection at every point on the line. This ensures consistent seal integrity, full compliance and the elimination of sealing errors.

Step-by-step operation:

-

The operator selects the product or works order on the OAL Line Terminal. With one click, the system automatically loads the correct seal inspection profile and configures the entire line.

-

The system sets up the printers for the selected job, ensuring the correct date codes, barcodes and label data are applied before products reach the seal inspection point.

-

Before seal inspection, the system confirms the presence, position and accuracy of packaging components, including labels, date codes and barcodes, using OAL’s AI-powered vision tools.

-

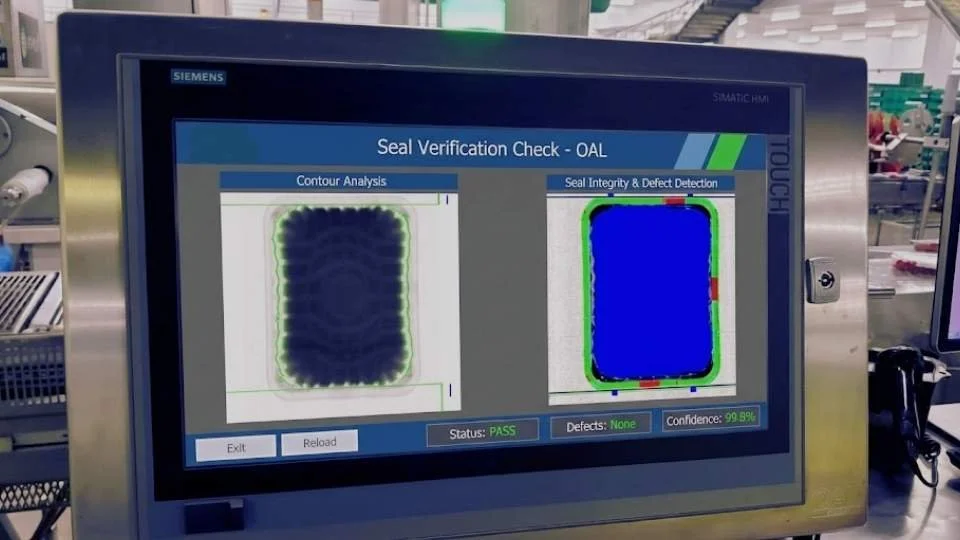

As each pack passes the inspection point, OAL’s seal verification system captures both thermal and visible images of the seal.

Thermal imaging identifies weak seals, trapped product and heat sealing defects

AI vision checks seal width, alignment and visible imperfections such as open or burnt seals

A PASS or FAIL result is sent instantly to the line for reject handling or line stop.

-

All seal images, results and inspection data are logged digitally for instant QA review. This creates a complete audit trail and supports Code of Practice compliance without the need for manual checks or paperwork.

Trusted by leading UK food manufacturers

OAL already supports automation and quality assurance across more than 2,000 production lines in the UK food industry.

“OAL systems massively helped us to increase efficiency on the production line. Increasing capacity by 50%.”

Pete Youé

Operations Director, Illchester Cheese

Frequently Asked Questions

Answers to the most common questions you might have.

-

Seal integrity verification uses advanced technology to inspect every seal on every package to ensure it is hermetically sealed and free from defects. This process is critical because sealing-related issues are the biggest cause of packaging complaints. Seal failures result in poor customer experience and can drive significant costs due to waste and associated environmental impact. Implementing in-line verification delivers 100% inspection, de-risking the production environment.

-

The system performs both thermal and visual inspection of every seal. It detects weak or incomplete seals, product trapped in the seal, misaligned or narrow seals, burnt or overheated seals, and any cosmetic defects. It also verifies labels, date codes and barcodes for full packaging compliance before products leave the line.

-

A thermal camera captures the heat signature of each seal immediately after sealing. Variations in temperature reveal hidden issues like trapped product, uneven sealing pressure or insufficient heat transfer. This identifies seal defects that are invisible to conventional vision systems or human inspectors.

-

The system supports flexible pouches, trays, lidded containers, film-sealed packs and MAP or gas-flushed products. It works with ready meals, raw protein, produce, high-risk products and anything that relies on heat sealing for food safety or retailer compliance.

-

Yes. The system has a compact footprint and can be retrofitted to existing conveyors, sealers or flow wrappers with minimal disruption. Most sites integrate it during normal planned downtime.

-

Thermal inspection eliminates many of the false passes common with vision-only systems. By combining thermal data with AI-powered visual inspection, the system achieves extremely high sensitivity and consistency, significantly reducing rework and customer complaints.

-

Yes. The system outputs instant PASS/FAIL signals that can trigger a reject mechanism or a line stop depending on your site’s quality control rules.

-

Every inspected pack generates a timestamped result and optional image log. QA teams can view thermal images, visible images, reject reasons and run histories to support traceability and retailer code of practice audits.

-

Yes. The system integrates with existing printers, weighers, sealers and PLCs. Product and job information is loaded automatically from your production plan to avoid operator error.

-

Minimal. Operators simply select the job on the OAL Line Terminal and the system configures itself automatically. Training typically takes less than an hour.

-

Most systems can be installed and commissioned within a few days, depending on the complexity of the line and number of products to be added to the Master Product Database.

-

Leak testers and manual sampling only check a fraction of production. OAL’s system inspects every pack inline, giving full assurance and eliminating the risk of defective seals reaching retailers or consumers.

-

We offer personalised demos at OAL’s headquarters and virtual sessions. You can bring your own products for live testing.

Let's get in touch and work together!

Contact us for a demo

+44 1733 394700

A1 Parkway Peterborough, PE2 6YN, United Kingdom

sales@oalgroup.com

Got a question? Call us now on

© Copyright | 2025 OAL Olympus Automation Ltd.