How to verify raw materials and products on a food production line

If you supply major retailers, you know that right-first-time production is essential for brand integrity and compliance. Across the UK and Europe, food manufacturers must demonstrate that the correct ingredients and components are brought to the line every time. As factories move from paper-based checks to fully digital processes, validation has become a core step in packaging verification and Autocoding.

This article explains how leading manufacturers validate raw materials, which technologies are used and how to integrate validation into an Autocoding or packaging verification system.

Why raw material validation matters

Every product, packaging, or formulation error carries risk ranging from rework and customer complaints to recalls and delisting. Validation addresses a single requirement: can you demonstrate that each material, ingredient and component is correct before production begins?

Whether you are confirming a flavour variant, checking the correct film is on the line, or ensuring allergen-sensitive ingredients match the job, validation provides a structured and auditable control step.

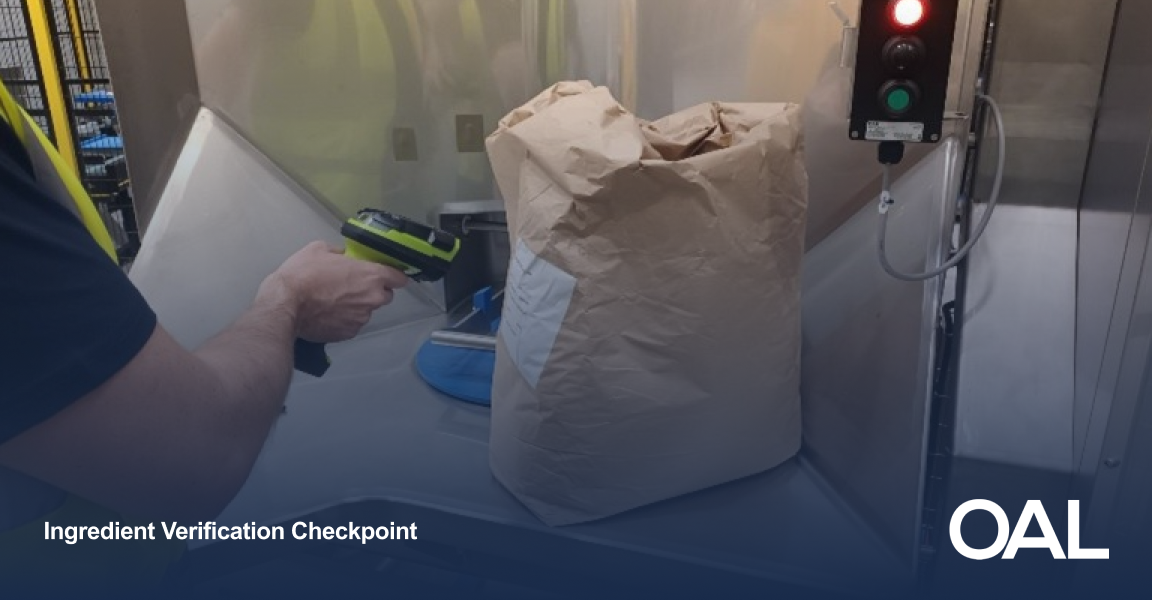

Validating incoming ingredients ensures the correct raw materials are approved before production begins.

Common challenges we see in food factories

Many sites face similar issues during changeovers or batch preparation:

Frozen WIP product brought to the line for date coding without confirmation it matches the scheduled job.

Raw materials not validated against the active product record in the Autocoding or ERP system.

Incorrect flavour or variant checks failing (e.g. sour cream & onion vs. cheese & onion).

Barcode verification limited to packaging not raw materials

No automated link to ERP or BOM data, creating opportunities for operator error

Over-reliance on AI inspection for allergen control where deterministic validation is required

These issues often occur because the checks rely on manual processes rather than integrated systems.

Raw material verification as part of Autocoding to verify each raw material against the BOM before production begins.

Technologies that support verification

1. Barcode validation

Barcode validation remains the most effective first step. Each raw material or component carries a 1D or 2D code that is scanned before use. The Autocoding system checks it against the active works order or BOM. If the material is incorrect, the line does not start. This provides a deterministic control aligned with retailer expectations.

For example, before a crisp line starts, the operator scans the flavour powder bag. If it’s not the correct flavour for the job, the line won’t start.

2. RFID tracking

For bulk or high-volume operations, RFID offers automated and hands-free validation. Each tote or container is tagged and detected as it approaches the line. This is well-suited to high-speed batching or liquid additions, where speed and traceability are essential and manual scanning is impractical.

At Jordan’s Ryvita, we deployed an RFID solution to track fat additions into mixers, ensuring positive release before production could continue. It’s fast, reliable, and requires minimal manual input.

3. Vision inspection

Vision systems can complement data-based validation by checking label type, colour, or pack format. They provide valuable anomaly detection, although they should not replace deterministic checks for allergen-sensitive materials. Vision is most effective as an additional safeguard within a wider validation process.

Integrated raw material workstations combine BOM checks, barcode/RFID scanning and optional vision inspection.

The integrated solution

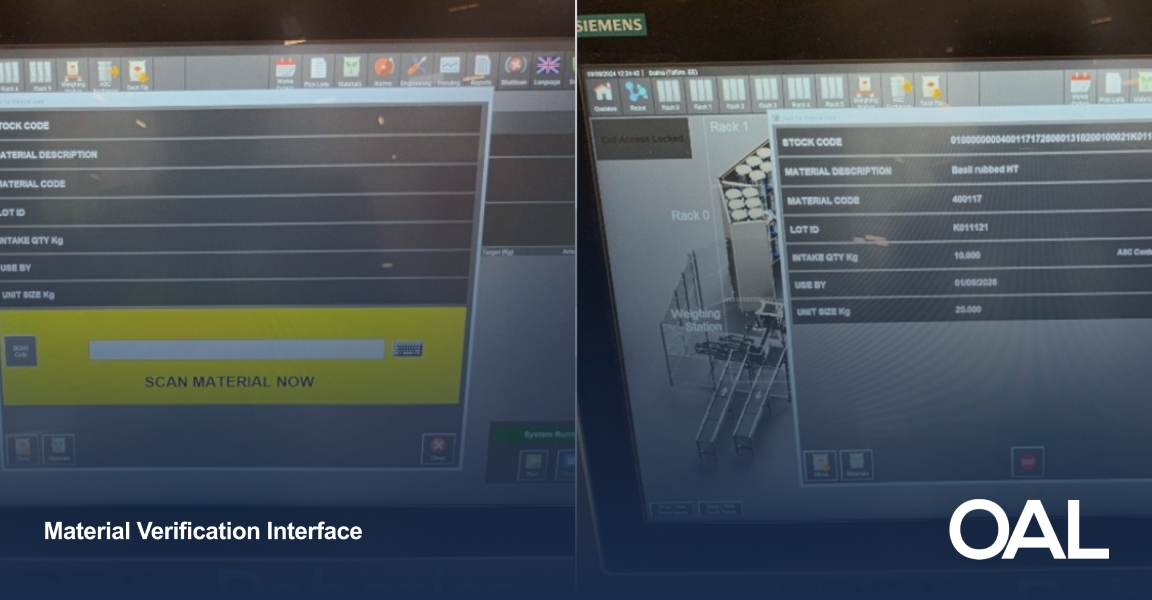

OAL delivers an integrated validation process that brings Autocoding, ERP data and factory devices together in a single workflow. This is the approach we implement for clients across the UK food industry to give them confidence that every material on the line is correct before production begins.

When an operator selects a job in the packaging verification system:

The BOM is loaded automatically from the ERP system

Each material is scanned using barcode or RFID

The system confirms a match before allowing the line to start

Optional vision cameras provide additional confirmation of labels or containers

This creates a consistent, auditable chain of custody from raw material receipt to finished product.

In sausage manufacturing, for example, operators scan meat batches and packaging components to confirm they match the recipe and job number before mixing or packing begins. At Premier Foods in Ashford, this process was integrated with their ERP system to validate raw materials against the job selected in the Autocoding system, resulting in zero material mismatches and faster line changeovers.

Additional considerations

Retailer compliance: M&S and other major retailers now expect automated validation steps as part of packaging and traceability audits.

Allergen control: Vision and barcode validation should be paired with strict data rules — allergens cannot rely on probabilistic AI decisions.

Scalability: Validation systems can start simple (manual scans) and grow to include automated gateways or RFID tunnels as throughput increases.

Does raw material verificaiton add value to your food business?

Yes. Incorporating raw material validation into your packaging verification system reduces the risk of recalls and strengthens retailer confidence. Many sites recover the investment within a year through faster changeovers, fewer investigations, and improved right-first-time performance.

Next steps

Every factory operates differently. If you want to explore how to introduce or improve raw material validation:

Book a free demo with our team

Request a tailored quote

Learn more at an OAL Food Manufacturing Seminar to see the technology in action

We will help you design a validation process that fits your site, integrates with your systems and strengthens confidence across your supply chain.