1D and 2D barcodes - what’s the difference?

Food manufacturers often ask: what’s the difference between 1D and 2D barcodes, and why do most retailers now require 2D? Here’s a short guide explaining how they work, why 2D barcodes have become the standard for packaging verification, and what that means for your factory

What are 1D barcodes?

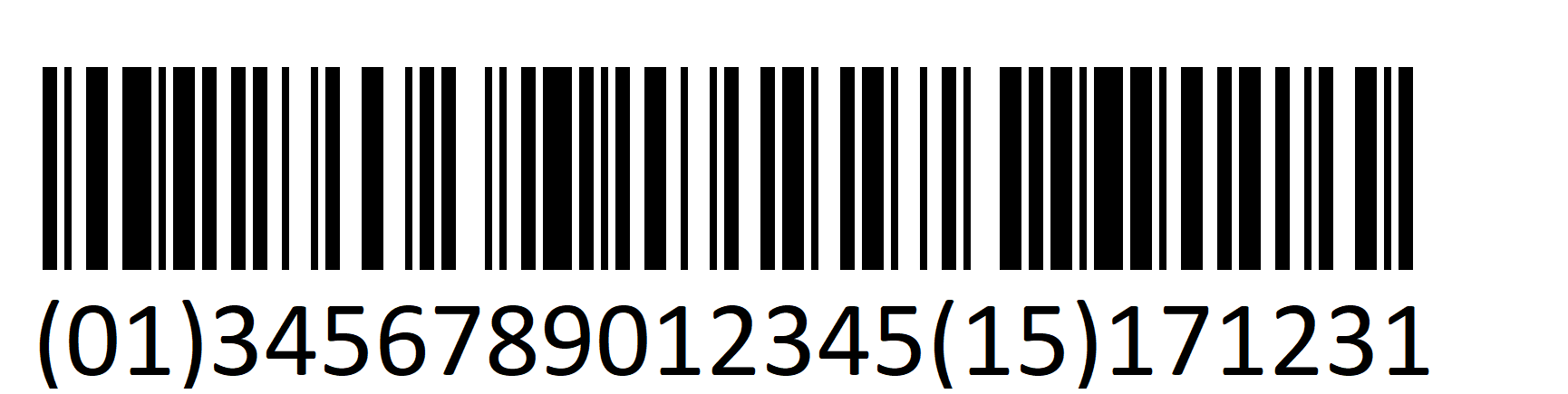

EAN128 1D Barcode

A 1D or single dimensional barcode is made up of vertical lines which vary in width on a contrasting background collectively forming an image. Alphanumeric data (i.e. letters and numbers) are encoded within the lines and spaces, although with a limit on the number of characters, and linked to a database where the data are housed. When the barcode is scanned using either a camera-based imaging scanner or laser-based scanner, the encoded data is decrypted revealing the information input within the database. The more data stored within, the longer the barcode.

1D barcodes are widely used in the retail industry as they’re better suited to applications where certain information, e.g. price, may change frequently yet the actual product’s identity number stays the same. In the food manufacturing industry, the retailer has control over the 1D barcode as it is this which links to the retailers’ tills for stock control and price monitoring.

2D QR Code

What are 2D barcodes?

2D barcodes are two-dimensional barcodes made up of a matrix of shapes (dots, squares, hexagons etc.) with data coded both vertically and horizontally. Depending on the type of 2D barcode, it can typically house more than just alphanumerical data, as well as holding much greater volumes of data than a 1D barcode at a much smaller size.

ECC200 2D Barcode

How food manufacturers use 2D barcodes

In the food manufacturing environment, 2D barcodes are used to check the packaging revision/artwork number to ensure that the product running is packed in the correct packaging. The manufacturer has control of this barcode, with a unique one for each packaging variation.

The changes on the packaging could be very slight, for example, a ‘new recipe’ flash could have been added or the packaging could be advertising a promotion. These adjustments may not be immediately obvious, which is why visual checks are not reliable especially when 60 packs are running past your eyes every minute! In certain circumstances, for example a new recipe, not having the right packaging could be fatal to the consumer if an allergen has been added so 2D barcodes can bring additional security to your packaging line.

Our Autocoding label & date code verification system safeguards your operations by scanning the 2D barcode on each and every product travelling down the packaging line and comparing the information to the job information programmed by the Technical Manager in the supervisory area of the system. This reliably ensures that the packaging is the correct variant allocated to that job and significantly reduces the costly risk of product recalls and withdrawals caused by label and packaging errors, as well as protecting the consumer from any incorrect allergen information.

By automatically scanning and verifying each 2D barcode, OAL systems ensure every pack is correct before it reaches the retailer, reducing manual checks and downtime.

Why 2D barcodes are essential for verification

We use 2D barcodes because these are the most reliable in the food manufacturing environment to help keep your factory, your products and your brand secure!

A major benefit of using 2D barcodes as opposed to 1D barcodes is that they can still work if slightly damaged, which is a huge benefit in the variable working conditions of a food manufacturing environment.

In addition, retailers rely on 1D barcodes for stock and price control; every time a price is altered, retailers must reset their tills to download the new information. If the packaging version information was held within the 1D barcode, the barcode would need to be extended to take on board the new information - taking up valuable packaging real estate - and the retailers would be forever resetting their tills! 2D codes offer a useful solution, allowing all of the information required by you, the manufacturer, to be kept separate in a very small space so that the packaging artwork is not disrupted.

Using 2D barcodes and implementing the OAL Connected system gives the manufacturer full control and a reliable way to ensure that the packaging used for a job is correct regardless of any major or minor changes that are made, however last minute, and may not be as noticeable to the human eye.

If a 2D barcode is scanned and the code does not match the one input for that job prior to starting production, then the line automatically stops, and an alarm and red light alerts the Production Manager of the error. The system will then request that the issue is resolved, the solution recorded and additional QA checks are carried out before production can recommence, protecting you from the financial and brand repercussions of a product recall.

Transitioning to GS1 Digital Link with OAL

GS1, in collaboration with retailers like Tesco, is spearheading an initiative to incorporate QR and other 2D barcodes on packaging. This movement, led by OAL, aims to enhance the consumer shopping experience and reduce food waste by up to 40%. The GS1 Digital Link standard enables these barcodes to contain comprehensive product information, such as unique identifiers, expiry dates, allergen details, and more.

OAL offers a suite of solutions to help businesses transition to 2D barcode systems:

Creation of QR/2D Codes: Seamlessly integrate various product and manufacturing data, sourcing information from ERP systems like SAP, Oracle, and Infor.

Printer Control and Printing: Manage inline printers to print QR/2D codes alongside other essential information, such as best-before dates.

Verification: Ensure that printed codes are accurate and legible, maintaining data integrity.

Onboarding Services: Provide training for your team on the new software and assist in migrating existing labels to the updated format.

24/7 Support: Offer round-the-clock support with a rapid response time to address any issues promptly.

By adopting OAL's solutions, businesses can align with the GS1 Digital Link standard, ensuring compliance and enhancing operational efficiency. Embracing 2D barcode technology not only meets evolving industry standards but also offers opportunities to improve product traceability, consumer engagement, and overall supply chain efficiency.