Code of Practice Compliance

Automated retailer compliance trusted by the UK’s leading food manufacturers

Stay audit-ready and eliminate product recalls with OAL Connected, the UK standard for packaging and product verification. Trusted by major retailers and protecting over 2,000 production lines, OAL’s compliance system ensures every product leaves your site correctly labelled, coded and traceable.

Built for Retailer Confidence

OAL Connected is designed to meet and exceed UK retailer Codes of Practice, including Tesco, M&S, Sainsbury’s, Morrisons, Aldi, Lidl, and Asda. The system provides complete packaging verification and traceability, ensuring compliance with BRCGS and GS1 UK standards

Proven on over 2,000 UK food production lines

Trusted by all major UK retailers

Eliminates packaging errors and costly product recalls

Creates digital audit trails for every job

Integrates seamlessly with your existing line equipment

Why Manufactureres Choose OAL

Industry Standard

The UK’s most popular compliance and packaging verification platform, OAL Connected handles complex labelling and packaging operations across high-speed lines with ease

Proven Expertise

With over 30 years of experience and more than 50 engineers, OAL delivers practical automation solutions that simplify compliance and enhance productivity.

Backed by innovation

Continuous investment in AI, machine vision, and automation drives the development of next-generation systems. Our £6.5 million Innovate UK-funded projects ensure you stay ahead of changing retailer requirements.

Seamless Integration

Integrates directly with your printers, cameras, and ERP systems for one-click control of your packaging line.

Always-on Support

Our UK-based support team of 15 specialists is available 24/7, 365 days a year. You can speak directly to an engineer within one hour, because downtime isn’t an option.

How it Works

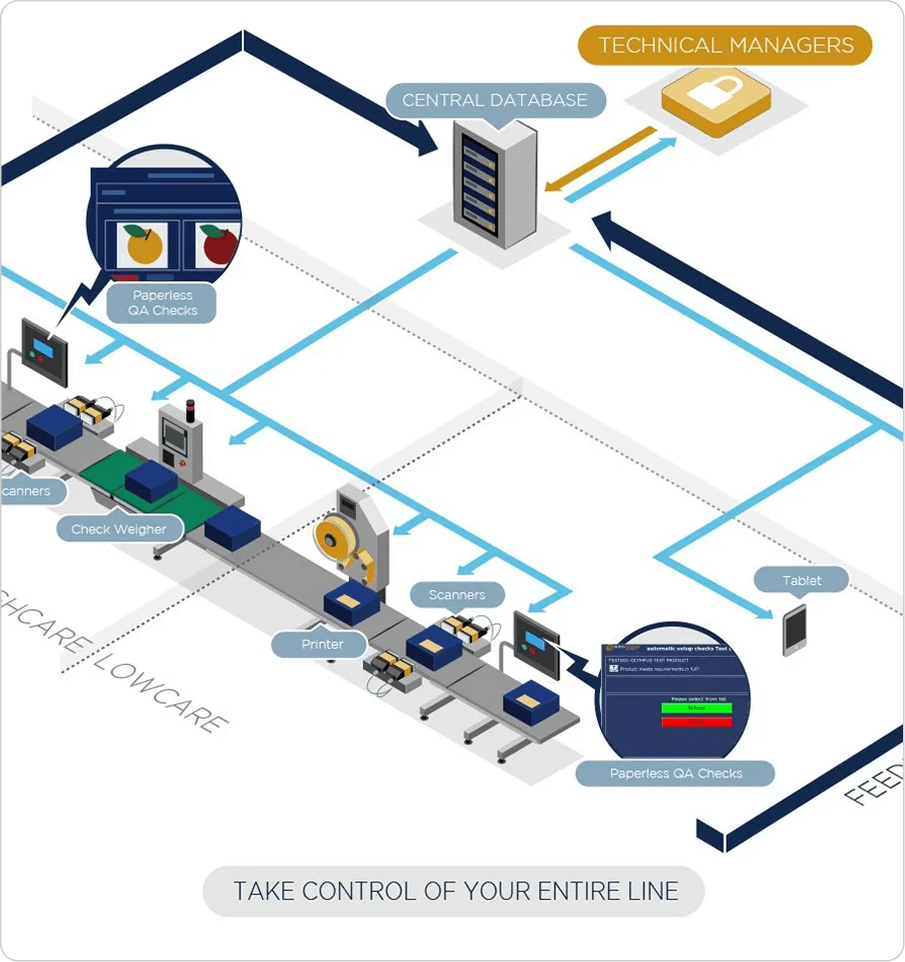

Our Connected system combines intelligent software with robust hardware to automate printer setup and verify every pack, eliminating date code and label errors before they cause problems.

Step-by-step operation:

-

The operator selects the works order or product on the OAL Line Terminal. With one click, the system automatically configures the line.

-

The system loads data from the master database and configures all printers with the correct date codes, batch codes, and variable data.

-

Integrated cameras confirm that barcodes, artwork, and label positions match the active job.

-

Optional APRIL Eye vision technology detects quality and print defects beyond barcode validation.

Challenge: Meet multiple retailer Codes of Practice and remove manual label checks.

Solution: Installed OAL Connected across all packaging lines.

Outcome: Passed all retailer audits, removed paper checklists, and improved operator confidence..

Customer Success

“Without a doubt I would recommend OAL to other manufacturers. This system is the failsafe.”

Sarah McGeehan

Group Technical Manager, Life Health Foods (M&S Supplier)

Why Leading Retailers Trust OAL

Certified GS1 UK partner for digital link QR codes

Approved by retailer technical teams for use in Code of Practice compliance

Proven across chilled, ambient, and fresh produce sectors

Authority

Display GS1 certification badge and Innovate UK funding logo.

Consensus

Include a scrolling carousel of customer and retailer logos.

Consistency

Include a short animation showing the standard OAL Connected deployment process.

Unity

Use team photography and on-site installation imagery to highlight collaboration between OAL engineers and customer teams.

Related Applications

APRIL Eye AI-powered label and product inspection

OAL Connected Office for centralised master data control

Fenceless robots for automated case and crate packing

Book your Compliance Consultation

Stay ahead of retailer standards with OAL Connected. Book a demo today to see how our system can protect your brand, simplify audits, and improve line efficiency.

Got a question? Call us now on

© Copyright | 2025 OAL Group, LLC