OAL Connected becomes first GS1 UK Approved packaging verification platform

We’re proud to share that OAL Connected has officially received GS1 UK Approved status, making it the first packaging verification platform in the UK to achieve this certification.

This recognition confirms OAL Connected’s full compliance with GS1’s global standards and marks a major milestone for the UK food sector as it transitions toward next-generation barcoding and traceability. With major UK retailers like Tesco piloting dynamic QR codes, OAL Connected gives food manufacturers the tools to stay compliant and futureproof.

The OAL team celebrates GS1 UK approval of the Connected platform at the Peterborough HQ

Left to right: Jake Norman, Faye Louch, Phil Tokens

Raising the standard for packaging verification

The GS1 UK product approval process involved a rigorous technical review, including a live demonstration and a full assessment of documentation. OAL Connected is now certified to support:

GS1 Digital Link QR codes

GTIN, SSCC and GS1-compliant data structures

Barcode symbologies including EAN/UPC, GS1-128 and GS1 DataMatrix

As UK retailers prepare for Project Sunrise, this certification ensures our customers are ready to meet new packaging data requirements with confidence.

“We built OAL Connected to deliver robust traceability and packaging integrity across food manufacturing. To have that independently validated by GS1 UK is a proud moment for the team, and a real win for our customers.”

Why GS1 certification matters

GS1 UK Approval confirms that OAL Connected has been tested against strict global benchmarks for barcode integrity, data quality and traceability.

With this capability, manufacturers can now print GS1 Digital Link-enabled QR codes inline, embedding variable data such as expiry dates directly onto packs for retailer systems and smartphone scanning.

“We are pleased to approve OAL Connected for its alignment with GS1 standards. Their platform demonstrates the identification and barcode compliance that helps the UK food sector meet growing expectations around traceability, data quality and supply chain transparency.”

See it in action at OAL HQ

To support this rollout, we’re running live automation seminars at our Peterborough headquarters. Attendees will see OAL Connected and other automation systems in action, with a focus on how to futureproof operations for compliance, efficiency and transparency.

OAL Featured on BBC Climate Documentary: Ready Meals – What They Really Mean for You

We’re proud to announce that OAL has been featured in the BBC’s new documentary Ready Meals: What They Really Mean for You, now streaming on BBC iPlayer.

The programme explores how food production can achieve net zero, and the innovative technologies helping to do it. Our APRIL™ robotic chef and Steam Infusion technologies are featured, demonstrating automated cooking at scale while cutting energy, water, and chemical usage.

The system was developed as part of Project Souper Green - our £2 million collaboration with Solina and Marks and Spencer, part-funded by the Department for Energy Security and Net Zero through the Industrial Energy Efficiency Accelerator, delivered by The Carbon Trust in partnership with Jacobs and Innovate UK.

Being featured on the BBC is a proud milestone for our team and a clear signal that automation and robotic solutions have a central role to play in decarbonising food production.

Watch the episode on BBC iPlayer to see how OAL delivers practical, scalable solutions for a more sustainable future. (OAL segment at 16:35)

Want to automate your food business? Get in touch to explore what’s possible.

Automation Trends in Food Manufacturing Seminar Series

Join our exclusive seminar series tailored for leaders in food manufacturing. Discover innovative technologies, engage in insightful discussions, and gain a competitive edge.

Automation is reshaping the future of food manufacturing, and this seminar series is your gateway to staying ahead. From artificial intelligence to robotics, our events are designed to showcase advanced solutions and spark meaningful conversations among industry leaders.

What You’ll Experience:

Live Demonstrations

Get to grips with the latest robotic and vision technologies shaping food manufacturing

Interactive Discussions

Participate in breakout sessions on automation trends, challenges, and opportunities for tailored solutions.

Networking Opportunities

Connect with industry experts, academics, and peers driving innovation in food manufacturing

Why Attend?

Exclusive Insights: Gain knowledge on cutting-edge automation trends and practical applications.

Tailored Solutions: Explore how automation can meet your specific operational needs.

Actionable Takeaways: Leave with clear strategies to implement and drive ROI in your business.

Register Your Interest

Complete the form below to express your interest. One of our team members will contact you shortly to confirm your attendance.

Upcoming Seminars:

Tuesday 25th February - FULLY BOOKED

Thursday 27th March

Thursday 15th May

Tuesday 3rd June

Thursday 4th September

Tuesday 6th November

Location:

All our events are held at OAL’s headquarters.

Address: OAL, A1 Parkway, Peterborough, PE2 6YN

Movember 2024 at OAL in aid of the Northamptonshire Charity Stroke Team Charity

This Movember, our team supported the Northamptonshire Healthy Charity by growing moustaches and raising awareness for their vital work.

Together, we raised a fantastic £2,820.00 to help support the Community Stroke Team with their amazing work!

This campaign has been about more than just questionable moustaches – it’s been about making a real difference. Every penny donated goes towards vital projects helping people and their families work through illness and the road to recovery.

Andy’s Story

Support for Stroke survivors is a cause very close to our hearts.

Last year, our colleague Andy, a popular presence in the office, suffered a stroke. Thanks to the exceptional support from medical services, especially the Community Stroke Team, Andy was able to achieve his primary goal of returning to OAL, a journey that has inspired us all.

This year, we rallied together to support the Community Stroke Team at the Northampton Health Charity and the invaluable work they do.

Every generous donation went towards helping people and their families work through illness and the road to recovery.

“I'm very proud of our team for taking on Movember to raise money for the Stroke Team!” enthused OAL Managing Director, Jake Norman. “If you've been lucky enough to work with Andy Sillence, you'll know he is Mr Sunshine Yellow. Following a stroke last year, we've been astounded by the grit and determination he has shown to return to work and we're thrilled to have him back! It was an obvious choice for us to raise money and awareness for the charity that supported him this Movember.”

About the Northamptonshire Community Stroke Team (CST)

The Northamptonshire Community Stroke Team (CST) is a respected service that focuses on delivering high-quality, tailored rehabilitation for stroke survivors. Their multidisciplinary team, including physiotherapists, occupational and speech therapists, rehab assistants/practitioners, and nurses, collaborates to help patients recover from, illness and regain independence.

Find out more about the amazing work the Community Stroke Team does HERE.

3 Key Takeaways from PPMA 2024: Showcasing the future of automation in food manufacturing

Our team exhibited at the PPMA 2024 show at the NEC, Birmingham in September. We showcased a number of cutting-edge automation technologies that are helping food manufacturers automate their food production lines. Here’s our 3 key takeaways from a very busy show:

1 - Automation is king!

Across the three days, we spoke to 782 food industry professionals.

Their feedback was clear: the industry is hungry for automation!

From fresh produce to bakery, each sector is suffering with labour availability and rising costs. People recognise automation can help and they’re looking for solutions.

It was great to share how we’ve helped food manufacturers like Worldwide Fruit and Agrana on their automation journey.

2 - AI-powered vision and 3D laser technology took centre stage!

If you fully automate your production lines, no human eyes will see your packs or products!

You’ll be reliant on technology to verify the quality of every pack.

We demonstrated how AI-powered vision technology is a game changer for inspection and a key enabler in their automation journey.

In the first demo, “Right Product” verification; the camera checks that the right product is being packed, for instance, detecting the difference between lasagna and a pasta bake.

The second demo, showed our 3D laser scanning solution showcased how we can create a 3D profile of every dough to eliminate defects and measure critical quality attributes like volume.

Jake Norman, OAL's Managing Director speaking with Camilla Young, Programme Lead for GS1 powered QR codes

3 - Leading the “Second Barcode Revolution”

Barcodes are changing!

We hosted a seminar with GS1 on the “Second barcode revolution” and how best to implement dynamic QR codes on packaging.

The change will require manufacturers to print key production information including batch numbers and date code information on pack.

We have proven solutions that can help you meet the GS1 requirements fast.

Read more about the introduction of dynamic QR codes in The Grocer article here.

OAL will be exhibiting at PPMA 2025. We look forward to welcoming you back next year as we continue to push the boundaries of innovation and provide the solutions that help drive the industry forward. Stay tuned for what’s to come—next year’s stand will be one you won’t want to miss!

The Grocer: The Second Barcode Revolution

A special report by The Grocer featuring OAL's Jake Norman, exploring the many opportunities the global transition to QR codes to industry and consumers alike.

OAL’s Managing Director, Jake Norman, was featured in a recent article by George Nott on “The Second Barcode Revolution” for The Grocer.

George’s report gives a fantastic overview of the power of these next-generation QR barcodes and why adoption is rapdily accelerating across the retail sector.

Please click on the button below to read the feature in full:

OAL appoints Nick Taylor as Operations Director

OAL, a market leader in automation, robotics and digital transformation solutions for the food manufacturing sector, has appointed Nick Taylor as its new Operations Director. Nick will be responsible for scaling business operations to meet the growing demand for OAL’s solutions.

Nick, far left, at a recent site visit to OAL's customer, Worldwide Fruit

“We are extremely pleased to welcome Nick to OAL,” said OAL MD Jake Norman. “Nick has extensive experience across all facets of food manufacturing and will ensure we continue to delight our customers as the business expands.”

Previously, Nick led Capital Investment at KraftHeinz, Telford and served as Site Director at one of Hovis’s manufacturing sites. Over the course of three decades, he has held operations and engineering roles at manufacturers, including Bakkavor, Coca-Cola Enterprises and KraftHeinz.

OAL was founded in 1993 by Harry Norman and quickly developed a strong reputation for pioneering the latest technology to solve the challenges faced by the food industry. From integrated MES/SCADA factory control systems to AI cameras verifying product packaging, date coding and robotic weighing systems, OAL has become the partner of choice for food manufacturers on a digital transformation journey.

Visit OAL at the PPMA Show on Stand A54, 24-26 September 2024

OAL leads “Second Barcode Revolution” roll-out to cut food waste

OAL, a leader in food manufacturing automation, is delighted to announce the launch of its latest software solution for creating, printing and verifying data-rich, on-pack QR and 2D codes designed to meet consumer demand for greater transparency of ingredient origins and methods of production. The software allows unique traceability and manufacturing data to be incorporated into on-pack 2D codes, improving consumer experience to identify allergens, significantly enhancing food safety and reducing food waste by up to 40%.

The OAL solution enables the creation, inline printing and verification of on-pack QR/2D codes containing critical information such as best-before date, allergens and batch data. The solution is in conformance with the GS1 Digital Link standard enabling consumers to access detailed product information in what is being called the “second barcode revolution”, while also enabling retailers to manage inventory more precisely, quickly identify expired products and provide consumers with detailed product information. OAL install inline camera technology to verify the integrity of every QR/2D code printed.

Leveraging GS1's barcode technology, OAL aims to enhance supply chain efficiency and product traceability. The OAL QR code solution stemmed from an initiative led by Tesco to reduce food waste in the supply chain. Tesco’s new initiative allows packs to be scanned by smartphones, and at the point of sale, sharing more information with consumers than the finite space on pack and standard barcode can offer.

Jake Norman, Managing Director, OAL, comments, “Our automated control systems already collect and store huge amounts of traceability data to ensure food safety. We know at a pack level the exact time and raw materials that have been used to make each product controlled by our system. The use of QR codes and the GS1 Digital link is a great way to expand the use of this data to grant consumers the transparency they’re urgently seeking and drive down food waste.”

OAL has pledged to support all manufacturers in integrating a range of QR/2D codes to their process, facilitating seamless data sharing and improving food safety. This comprehensive data ensures product authenticity and simplifies recall processes. OAL’s printer agnostic solution can integrate and control all printer brands. The solution can be retrofitted to existing packaging lines. The solution is available now for new and existing customers.

For more information, please visit https://www.oalgroup.com/gs1-new-barcode

7 Key Moments from Anuga FoodTec 2024: Where AI Vision Tech and Robotic Automation Took Centre Stage!

Last week, our team embarked on an exciting journey to Cologne, Germany, where we showcased our cutting-edge AI vision technology and robotic automation at the one and only Anuga FoodTec Exhibition.

Last month, our team travelled to Cologne, Germany, where we showcased our cutting-edge AI vision technology and robotic automation at the one and only Anuga FoodTec Exhibition.

Here are the top 7 moments that put OAL on the centre stage.

1. Robots Ruled the Roost!

Our robotic weighing system and cooking system stole the show with its mesmerising precision and efficiency when weighing raw materials. Manufacturers were relieved to find a solution to overcome their ongoing labour availability challenges.

2. AI Vision Tech Magic!

Say goodbye to human error and hello to precision perfection! Our AI vision technology wowed the crowds with its ability to analyse products from component recognition to date code verification and even checks for allergen information.

3. Busiest stand award 2024!

Anuga FoodTec was the ultimate playground for innovation, and we were proud to be at the forefront of the action. We even won the award for most popular stand, with over 500 registrations recorded, that’s a lot of demos.

4. Interactive Experiences!

Who says tech exhibitions have to be boring? Gone are the days of highly choreographed software demos. Visitors got to choose the inspection and we showed them how to train the AI and make the check in less than 5 minutes! The result? Smiles, laughter, and a newfound appreciation for the magic of OAL’s APRIL Eye.

5. Tech Talks Galore!

Knowledge is power, and we were thrilled to share our expertise with eager attendees. From demystifying AI to exploring the future of robotic automation with weighing and cooking, we left no stone unturned in our quest to educate and inspire.

6. Industry Insights!

Anuga FoodTec wasn't just about showcasing the latest technology—it was also a hub of industry insights and trends. From the rise in codes of conduct to the growing demand for sustainable food tech solutions, we gained invaluable knowledge that will shape the future of our industry.

7. Networking Nirvana!

Anuga FoodTec brought together the best and brightest minds in the food tech world, providing the perfect opportunity to connect, collaborate, and forge new partnerships.

Our time at Anuga FoodTec Exhibition was inspiring. It was a celebration of innovation, creativity, and the boundless possibilities of AI, automation and robotics, with OAL positioned as a strong leader in game-changing solutions in food manufacturing.

OAL appoints Jake Norman as Managing Director

OAL, a market leader in automation, robotics and digital transformation solutions for the food manufacturing sector, has appointed Jake Norman as its new Managing Director. Founder, Harry Norman will remain on the board.

Jake Norman has over a decade of experience in automation and a proven track record of developing long-term customer relationships. He joined the board two years ago as Sales Director, taking P&L responsibility for the business and winning a number of new customers. Notably, he has recently secured a £2 million part-government funded Carbon Trust project to deploy the company’s robotic chef with Marks & Spencer and Solina.

“I’m proud to lead the family business into a new era as we navigate the fantastic opportunities automation and robotics present to our customers,” comments Jake Norman, Managing Director, OAL. “We’re inspired by Harry’s visionary approach to automation, he’s built an exceptional engineering team that help our customers succeed and I’m looking forward to building on this foundation.”

OAL was founded in 1993 by Harry Norman and quickly developed a strong reputation for pioneering the latest technology to solve the challenges faced by the food industry. From integrated MES/SCADA factory control systems to AI cameras verifying product packaging and date coding and robotic weighing system, OAL has become the partner of choice for food manufacturers on a digital transformation journey.

Harry Norman, Founder, OAL added, “Jake’s passion for technology and his understanding of the food manufacturing sector make him the ideal leader for OAL as we look towards an exciting future. I am proud to see him take on this role and have every confidence in his ability to steer OAL to new heights.”

Visit OAL at Hall 10.1, Stand F-069 at Anuga Foodtec Cologne, Germany, 19-22 March 2024 to learn more.

OAL Announce Seamless Integration with NiceLabel

OAL has launched a full integration with NiceLabel, enhancing their label and date code verification system, OAL Connected. This move aids food manufacturers in automating labeling and ensuring compliance. For businesses using Dataguard, OAL provides an easy transition. NiceLabel, a renowned name in label design, guarantees quality and industry-standard compliance. The partnership promises streamlined workflows, increased efficiency, and precise label verification. OAL's award-winning support backs this integrated solution.

OAL is excited to announce the release of a full and seamless integration to NiceLabel as part of our label and date code verification system, OAL Connected.

“At OAL we understand the pressures that food manufacturers are under to meet the label requirements of their retailers. We believe that this integration will not only support them in automating labelling and verification but will provide a much better user experience for our customers,” commented Jake Norman, Sales Director, OAL.

For businesses currently using the end-of-life Dataguard label printing software, OAL and Nicelabel offer a proven switching path. Join other fresh produce businesses including Wealmoor and Worldwide Fruit who have already benefited from switching to OAL for a robust label printing solution.

Read more about how Wealmoor switched from Dataguard to OAL here.

Why NiceLabel?

For those unfamiliar, NiceLabel is one of the most respected names in the label design industry. The solution provides a comprehensive and powerful suite of tools to help manufacturers create, print and manage labels that are both high-quality and meet rigorous industry standards.

“Working with site teams, we’ve been able to significantly reduce the number of label design templates, simplifying their process. NiceLabel is easy to use and provides compliance with retailer codes of practice” shared Faye Louch, OAL Trainer.

How OAL integrate with NiceLabel?

We have integrated NiceLabel with the OAL system in the same way as other label design software such as Clarisoft and Markem Colos.

When an operator selects a job on the OAL system, the variable field data is pulled from the OAL Master Product Database and integrated into your template design created in NiceLabel. This then instructs and controls the printer, ensuring the right information is printed on the label. The integration works for both offline and online printing with the OAL system monitoring and alerting if printers enter fault status in accordance with retailer codes of practice.

The Value This Delivers for You

We believe this integrated solution provides significant value for those looking to migrate from Dataguard or anyone looking for a comprehensive and intuitive labelling solution. The benefits include:

A Unified Process: Users can design a label in NiceLabel, and then seamlessly verify its integrity and compliance using our verification system. This means a smoother workflow and reduced risk of error.

Enhanced Efficiency: The need for multiple systems or manual data entry is eliminated. When you design a label in NiceLabel, the details are automatically synchronised with the OAL master product database.

Greater Accuracy: With the automated synchronisation between the two platforms, you reduce the risk of oversight or data discrepancies; what you design is what you verify.

Find Out More and Get Started

If you're considering switching label design to NiceLabel, now is a great time! Integrating with OAL means you’re not just getting a great label design tool, you're also getting a comprehensive verification solution that ensures retailer code of practice compliance and our award-winning customer support team is there to support you 24/7, 365 days a year.

We would be more than happy to explain the solution further and answer any specific questions you may have. Simply reach out to the OAL team – contact us.

Navigate the Future of Fresh Produce at Fruit Focus 2023 with OAL

Join OAL at Fruit Focus. We are excited to share that Jake Norman, OAL's Sales Director, will be delivering a seminar from 9:00 to 9:20 am. His talk will tackle the challenge of automating and digitalising fresh produce production, sharing key learnings from a ground-breaking automation project with M&S and Solina Carbon Trust Project.

The esteemed Fruit Focus 2023 event returns to the UK's fruit industry stage on 12th July 2023. Hosted at NIAB, East Malling, Kent, England, the event will run from 09:00 to 17:00. Fruit Focus is your gateway to new advancements in fresh fruit sectors, wine-making, and viticulture.

Fruit Focus is recognised as the UK's leading technical event for the fruit industry. It is a valuable meeting point for industry professionals to update themselves on recent technological innovations and trends. The event creates an ideal environment for networking with colleagues and exchanging industry-specific insights.

We are excited to share that Jake Norman, OAL's Sales Director, will be delivering a seminar from 9:00 to 9:20 am. His talk will tackle the challenge of automating and digitalising fresh produce production, sharing key learnings from a ground-breaking automation project with M&S and Solina Carbon Trust Project.

This project, known as the Souper Green Project, represents a milestone in OAL's journey to revolutionise the food processing landscape. With the support of a £2 million grant from the Department for Energy Security and Net Zero’s Industrial Energy Efficiency Accelerator (IEEA) and the backing of Marks and Spencer PLC, the Souper Green project embodies the transformative power of sustainable automation.

Jake's presentation at Fruit Focus 2023 provides a unique opportunity to delve into these advancements, understand their potential impact on the fruit and wine sectors, and explore how innovation and digitalisation can lead to a more sustainable future.

Your participation at Fruit Focus 2023 is a step towards that future. Take advantage of the free pre-registration and access a wealth of benefits including the Fruit Forums, NIAB Research Tours, and the Growing Kent & Medway Innovation Showcase. There's a wealth of knowledge to be gained and connections to be made. We look forward to welcoming you for a day of growth and discovery at Fruit Focus 2023.

Partners & Sponsors:

Leading the Transformation: OAL Introduces Steam Infusion and APRIL™ Robotics to the Chemical Industry at Expoquimia 2023

OAL, in collaboration with our esteemed System Integrator partner, Raimaber, are proud to be exhibiting at Expoquimia 2023. Join us in Barcelona, Spain, from 30 May- 2 June, as we redefine the landscape of chemical manufacturing, showcasing groundbreaking innovations that will shape the future of the industry.

Date: 30 May - 2 June, 2023

Location: Gran Via, Hall 3, Level 0, Street D, Stand 119 - Barcelona, Spain

Website: expoquimia.com/en

OAL, in collaboration with our esteemed System Integrator partner, Raimaber, are proud to be exhibiting at Expoquimia 2023. Join us in Barcelona, Spain, from 30 May- 2 June, as we redefine the landscape of chemical manufacturing, showcasing groundbreaking innovations that will shape the future of the industry.

At OAL, we aim to revolutionise industrial processes through cutting-edge technologies. Our groundbreaking Steam Infusion technology has unlocked new possibilities within chemical manufacturing, offering unrivaled control and efficiency. Witness the transformative power of Steam Infusion as we showcase our state-of-the-art demo unit at Expoquimia.

Alongside our partner, Raimaber, renowned for their expertise in system integration, we are proud to introduce APRIL™ Robotics, the world's first robotic Weighing System, initially engineered for the food and beverage manufacturing industry. We are thrilled to share that APRIL™ Robotics is perfectly poised to support the chemical industry as well, with its adaptability and versatility. Marvel at the precision and efficiency of APRIL™ Robotics as it seamlessly integrates into your manufacturing processes, ensuring accurate and consistent weighing, minimising waste, and optimising productivity. Experience the potential for enhanced operational efficiency and discover how APRIL™ Robotics empowers your workforce to achieve new levels of accuracy and productivity.

At Expoquimia 2023, we invite you to visit our dedicated stand, where our partner will be showcasing the synergy of Steam Infusion and APRIL™ Robotics. Immerse yourself in our informative video display and witness how these innovations redefine processes, enhance productivity, and revolutionise the chemical industry. Engage in conversations with industry experts, exchange ideas, and explore collaborative opportunities as we collectively drive the transformation of the chemical sector.

See you at the event. Register for the event at the link bow.

Charting the Future of Fresh Produce: Join us at 'Festival of Fresh' 2023 event

As the UK faces a slew of challenges – a labour shortage, rising energy consumption, and the urgency of maintaining food manufacturing excellence, the Festival of Fresh 2023 arrives as a beacon of innovation and transformation. We're proud to announce that Jake Norman, Director at OAL, will be one of the esteemed speakers at this year’s event. Jake will be sharing valuable insights from our groundbreaking £2m Carbon Trust project, delve into the lessons learnt from this transformative project, and will be offering a fresh perspective on how businesses can conquer the challenges of rising labour and energy costs. He will also share success stories from automation deployments. Join us on June 21. Registrations are open now!

Jake's address

This summer, the UK's fresh produce industry is gearing up for an event that promises to be an invigorating celebration of British harvest and a forum for insightful discussions on emerging challenges. The Festival of Fresh 2023, organised by the Fresh Produce Journal (FPJ Live), is set to take place on the auspicious Midsummer’s Day, 21st June 2023, at Alconbury Weald, Cambridgeshire.

In the recent past, over 300 industry leaders and experts have flocked to this distinguished gathering, revelling in the spirit of innovation and camaraderie. This year, the event promises to be more insightful and engaging, given the current trials we face - labour shortages, energy price surge, and raw material costs.

OAL is proud to announce that Jake Norman, Director at OAL, will be one of the esteemed speakers at this year’s event. Known for his stance on the integration of technology in the fresh produce industry, Jake will be sharing valuable insights from our groundbreaking £2m Carbon Trust project.

The project, in collaboration with M&S and Solina, demonstrated the power of digitalisation and automation in the manufacturing sector. Achieving an astounding 80% reduction in energy consumption, this project stands as a testament to the potential of smart manufacturing.

Jake will not only be sharing insights from this transformative project, but he will also bring to light successful automation implementations in the fresh produce sector, highlighting some of our elite clients who achieved remarkable results with digitalisation. Participants can look forward to an engaging demonstration of the software and technologies that underpin the success of these advancements.

As we celebrate the best of British fresh produce at the Festival of Fresh, we also seek to equip ourselves to better address rising concerns in the UK industry. Jake Norman's insights into the power of digitalisation and automation aims to guide the audience with a way forward strategy- a path to overcome labour shortages, reduce energy consumption, and maintain high-quality produce more efficiently.

Join us at the Festival of Fresh 2023 as we explore the future of our industry, showcasing the potential of smart manufacturing to revolutionise the way we deliver food manufacturing excellence.

Registrations are open now!

Souper Green: Pioneering Robotics to Revolutionise Soup and Sauce Manufacturing in the UK

Olympus Automation Ltd. (OAL) is proud to announce the launch of its £2 million Souper Green project in partnership with Marks and Spencer PLC (M&S) and Solina. The project, supported by grant funding from the Department for Energy Security and Net Zero’s Industrial Energy Efficiency Accelerator (IEEA) programme, aims to transform the soup and sauce manufacturing industry by deploying an innovative APRIL™ Robotics Cooking Cell, which promises significant energy and carbon savings. The project's industrial demonstration will take place in Leeds, West Yorkshire, United Kingdom.

Peterborough, United Kingdom - April 24, 2023 - Olympus Automation Ltd. (OAL) is proud to announce the launch of its £2 million Souper Green project in partnership with Solina and supported by Marks and Spencer PLC. The project, supported by grant funding from the Department for Energy Security and Net Zero’s Industrial Energy Efficiency Accelerator (IEEA) programme, aims to transform the soup and sauce manufacturing industry by deploying an innovative APRIL™ Robotics Cooking Cell, which promises significant energy and carbon savings. The project's industrial demonstration will take place in Leeds, West Yorkshire, United Kingdom.

The Souper Green project is part of the Industrial Energy Efficiency Accelerator (IEEA) programme- Phase 4 project, funded under the Net Zero Innovation Portfolio (NZIP) and supported by the Department for Energy Security and Net Zero (DESNZ) IEEA through its Net Zero Innovation Portfolio. It seeks to fund industrial scale demonstrations of novel technologies that can reduce energy consumption, maximise resource efficiency, and cut carbon emissions. It is managed by the Carbon Trust with support from Jacobs and Innovate UK KTN.

APRIL™ Robotics Cooking Cell, a fully automated robotic food processing system, is designed to improve Clean in Place (CIP) processes and utilises OAL's Steam Infusion technology. By incorporating a lightweight cooking vessel, the system allows for more efficient heating operations and easier cleaning, leading to an impressive 80% energy savings from production trials. Additionally, the system's highly accurate robotic ingredient weighing system minimises ingredient waste.

The Souper Green project builds on OAL's 2015 "APRIL" program, which aimed to develop the world's first robotic-based food processing system. A pilot plant was successfully installed at the University of Lincoln's National Centre for Food Manufacturing (NCFM) at Holbeach. A development system (TRL7) is now operational at Go-Tan, a Dutch food manufacturer, producing 2.4 tonnes per hour (T/Hr) of chilli sauces.

The UK demonstrator will replicate the Go-Tan equipment with specific CIP enhancements, aiming to deliver a fully operational 2T/Hr production unit (TRL9).

Retailer M&S endorses the project as part of its Plan A commitment to support suppliers in reducing their carbon footprint and reaching net zero.

Solina, a food manufacturer and supplier to Marks and Spencer plc, plans to install OAL's robotic food processing system to significantly reduce energy consumption, enhance efficiency, and create a more sustainable production environment. For more information about the Souper Green project, please visit https://programmes.carbontrust.com/ieea.

In addition, OAL will be showcasing their automation systems at the Smart Manufacturing Showcase 2023 on Thursday 14 September at the National Centre for Food Manufacturing in Holbeach, United Kingdom. The event will provide an excellent opportunity for interested parties to learn more about OAL's innovations and the future of food manufacturing. For more information on the event registrations, follow us on LinkedIn at: https://www.linkedin.com/company/oalgroup

About the Industrial Energy Efficiency Accelerator (IEEA)

The IEEA is a four year programme funded through the Department of Energy Security and Net Zero’s (DESNZ) Net Zero Innovation Portfolio (NZIP), a £1 billion fund announced in the UK Prime Minister’s ten point plan for a green industrial revolution, to accelerate the commercialisation of low carbon technologies, systems and business models in power, buildings, and industry. £8 million in funding have been made available to fund demonstration projects through Phases 3 and 4 to demonstrate 15 innovations.

More information on: carbontrust.com/ieea & https://www.carbontrust.com/news-and-insights/news/pioneering-energy-efficiency-tech-wins-government-grants

DESNZ IEEA: Proud Facilitators and Collaborators

OAL 3 Peaks Challenge 2023

We’re hiking the 3 Peaks in June to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

We’re hiking the 3 Peaks to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

In June, a team from OAL will be putting down the tools and stepping away from our keyboards to take on the 3 Peaks Challenge in under 24 hours!

The 3 peaks are made up of Ben Nevis (1,344m), Scafell Pike (978m) and Snowdon (1,085).

We‘re starting on Saturday 23rd June with Ben Nevis, hopping in the van down to hike Scafell Pike, and finishing in the early hours of Sunday morning at the top of Snowdon.

Will it be a software, mechanical, design or electrical engineer to reach the top of Snowdon first?

We’re raising awareness and money for StrongMen, a great local charity that has helped us overcome the mental health challenges of bereavement.

If you would like to donate, you can here: https://www.justgiving.com/fundraising/oal-3peaks

SafeContractor accreditation 2022/23

We’re delighted to confirm that we’ve received SafeContractor accreditation for the seventhyear in a row, in recognition of our dedication to health and safety, for our own teams as well as how we work to protect our customers when on-site. When you work with OAL, you can be sure you’re in safe hands partnering with a responsible company.

We’re delighted to confirm that we’ve received SafeContractor accreditation for the seventh year in a row in recognition of our dedication to health and safety, for our own teams as well as how we work to protect our customers when on-site. When you work with OAL, you can be sure you’re in safe hands partnering with a responsible company.

Alcumus SafeContractor is a leading third-party health and safety assessment scheme initiated by the UK government under Safety Schemes in Procurement (SSiP), promoting a minimum standard of health and safety assessments, which helps customers to identify which companies meet the UK’s rigorous health and safety requirements. The accreditation is a sign of professional and credible contractor business, and all listed businesses can be found by registered customers via the client web portal. For any customers who are not clients, further information can be found on the SafeContractor website.

Throughout the rigorous accreditation process we provide examples of all our health and safety paperwork, demonstrating that the way we work meets legal industry requirements. This includes risk assessments, method statements, COSHH assessments and working at height, to name just a few!

A SafeContractor certificate is applicable to most sectors although it is particularly relevant to food manufacturing (our specialty) due to the number of contracted services. The SafeContractor seal of approval guarantees that we’re doing all we can to adhere to the very highest standard of health and safety and legal compliance, providing you with peace of mind when our teams carry out work on your sites.

SafeContractor confirms that we’re as dedicated to H&S as you are. Get in touch today for your upcoming projects!

Net Zero Food Manufacturing 2022 Round Up

On 16th June 2022, we explored the routes to net zero food manufacturing at the National Centre for Food Manufacturing (part of the University of Lincoln). A big thanks to our awesome customers, fascinating speakers and cutting-edge technology partners for making it a fascinating day!

On 16th June 2022, we explored the routes to net zero food manufacturing at the National Centre for Food Manufacturing (part of the University of Lincoln). A big thanks to our awesome customers, fascinating speakers and cutting-edge technology partners for making it a fascinating day!

The scene was set with insights and perspectives from academia, energy and finance:

Ling Sin Fai Lam, Shore Capital, highlighted the growing requirements for businesses to validate their “green” credentials.

Grant Barr, EON, explained the changing energy environment as the “spark gap” is reduced and the major benefits of consuming energy outside busy periods.

Wayne Martindale, University of Lincoln, reviewed the food industry's progress in decarbonising and shared the latest research projects in the field.

Bring on the robots!

With the scene set, we were joined by two pioneering food businesses using OAL robotic systems in the processing area to cut energy and improve production efficiency, quality and safety. Followed by a demonstration where we manufactured a net zero soup using the APRIL Batch cooking system.

Bing Go, Go Tan, explained how they have moved from traditional steam jacketed cooking vessels to a fully automated APRIL robotic cooking system.

Benoit Wissoq, Agrana shared their approach to automating powder handling with APRIL Powder Weighing. Watch the video below.

OAL demonstrated the APRIL batch cooking system by cooking and cooling a “net zero” batch of pea and mint soup. Saving the planet never tasted so good!

Alan Oakley, KUKA Robotics talked about how they support OAL with R&D and support customers locally through their extensive network.

Solving the energy problem

As the old maxim goes, what gets monitored, get’s managed. Our ability to collect, the right data, contextualise and drive action is fundamental to improving the energy efficiency of food businesses. Both end user case studies explained the need to put people at the heart of automation programmes.

James Judge, Berry Gardens focused on the need for “story telling” and “de-geeking” as part of the digitalisation of their new packhouse. Watch the video below.

Matthew Beacham, Wealmoor explained the skills and approach to automate their packaging lines and save energy by preventing human error. Watch the video below.

Inductive Automation and Ethan Stone, OAL shared how we use the Ignition SCADA/MES platform to present shopfloor data to end users easily. Watch the video below.

Thomas Flude, Cognex, demonstrated new vision and artificial intelligence technology can be quickly deployed to cut food waste.

Energy reduction funding

In our final session, Mark Swainson, University of Lincoln and Jenni McDonnell MBE, KTN, highlighted the current funding opportunities for energy and carbon reduction projects.

It truly was a varied day and we’re very grateful to all those attendees who came and participated so enthusiastically - we enjoyed every minute!

If you missed the event and want to hear more, get in touch and we can arrange a meeting with our experts.

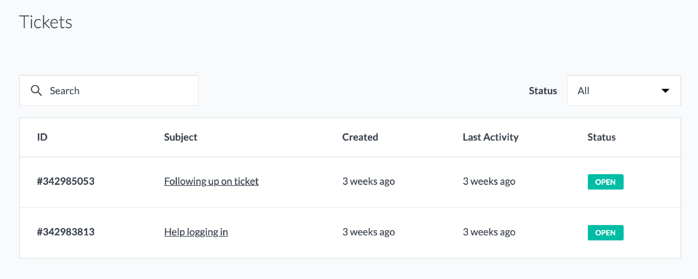

OAL customer support ticket portal

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

Customer Ticket Portal

To access the customer portal, please contact OAL and we’ll enable the portal for your account.

You’ll be sent an email to register using your work email address.

Once registered, click here to login to the ticket portal.

The portal provides the following functionality:

User account and login to OAL Customer portal.

Visibility and communication history for all tickets within your organisation.

Ability to raise a ticket.

If you need any assistance or have any feedback, ring +44 1733 394701 or email support@oalgroup.com

Harry Norman receives Lifetime Achievement Award

We’re delighted to announce that Harry Norman won the Lifetime Achievement Award at the Food Processing Awards 2021 in Coventry for his contribution to the food industry as an inventor, entrepreneur and innovator. Here we share the story that led to this fantastic achievement.

We’re delighted to announce that Harry Norman won the Lifetime Achievement Award at the Food Processing Awards 2021 in Coventry for his contribution to the food industry as an inventor, entrepreneur and innovator. Here we share the story that led to this fantastic achievement.

Harry’s background

Over the course of a career spanning over 30 years Harry has dedicated himself to innovation, determined to shake up the food industry and improve how our food is made. He was once quoted as saying, “If people say you can’t go through that door, then I get a chainsaw and make my own door.” It’s this relentlessness and drive for success that has characterised Harry’s career, guiding him towards continuous innovation to meet evolving customer needs.

While studying control engineering at Coventry University, Harry Norman fell in love with automation and robotics. Following just a few years in industry, the ever-entrepreneurial Harry was 28 when he decided to build OAL. A newly married father of two very young children, it was a bold decision to set up a business on his own, especially as the family’s main breadwinner. But it was a risk that soon paid off as the company was profitable from the very first year.

Innovating at OAL

Propelled by customer demand for automation, OAL soon became a one-stop shop for turn-key processing systems comprising design, automation and support. Developing strong relationships with some of the biggest names in the food industry, Harry has led the OAL team to complete hundreds of projects, delivering high quality results and outstanding support.

His vast experience in the food industry and free-thinking has helped him to spot trends and stay ahead of the curve, starting with the invention of Autocoding and the launch of the OAL Connected suite of software solutions, which has helped to transform packaging lines and increase food safety.

Spurred on by this success, and against the backdrop of an industry stretched by rising costs, Harry was convinced that food manufacturing needed to change. He knew OAL could lead the charge, taking the strategic decision to set up a dedicated innovation team. This pivot led to significant investment in new technologies to disrupt the industry, starting with the acquisition of the game-changing cooking technology, which was rebranded to become Steam Infusion, in 2013.

Not content with acquiring technology, his next conquest was in the field of robotics. His inventions under the APRIL Robotics brand, including a robotic chef and weighing system, have been described as the greatest processing innovation in the last twenty years by one of the largest FMCG companies in world.

Not just an inventor

But it’s not all work. His competitiveness in business is matched only by his competitiveness in his personal life. A keen cyclist and runner, he has completed a variety of challenges, from marathons to cycling races, with customers and to raise money for charity. He’s also a consummate storyteller, entertaining the OAL workforce and customers alike with his one-of-a-kind humour.