Heinz Secure Infant Formula Packaging Integrity with OAL System

100% read rates on spinning cans at a rate of 97 per minute to secure packaging integrity of baby formula for Heinz.

Customer

At the HJ Heinz factory in Cumbria, UK, baby milk powder is manufactured and packaged ready for distribution overseas. Due to the sensitive nature of the products, accurate barcode reading is essential to ensure the correct products are identified and shipped to the correct customer.

Challenge

The site was using a label verification system from another supplier where one element could only read ladder barcodes. Although a separate system was created to read the picket fence barcodes, the readers could not cope with the 97 cans per minute high-speed production. Heinz were keen to upgrade to a more reliable system which could achieve 100% read rates, eliminating any risk of packaging errors.

“Heinz chose the OAL Autocoding system because they were the only suppliers we reviewed to offer 100% read rates on products. The integrated quality checks on the Autocoding system and ability to offer 24-hour support have added significant value to the business.”

Solution

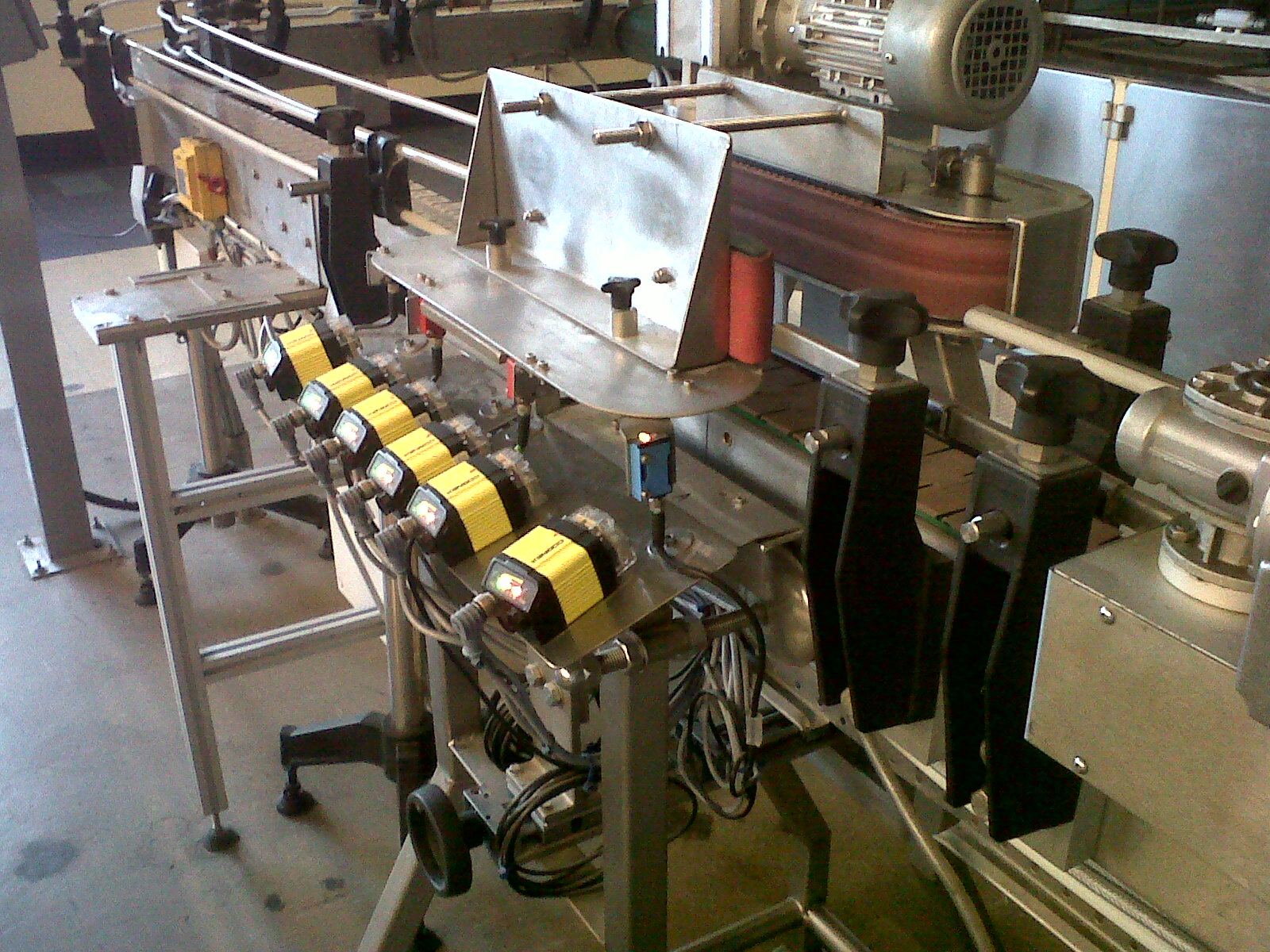

OAL installed their Autocoding system using six Cognex DataMan 302X readers, enabling at least two of the readers to read the code on the can as it rotated through 360 degrees. Importantly the system was able to handle the convex structure and reflective surface of the large cans. If incorrect barcodes or ‘no reads’ are detected, alarm beacons and display screens alert the operators who will stop the line and clear the defective product to ensure no incorrect product continues into the packaging area.

Read rates are reported as part of the standard OAL Autocoding system, allowing for easy monitoring of production performance. The system also links to the site’s Domino inkjet printers and Markem case printers to ensure the correct dates are printed on each pack, ready for shipment.

Results

Autocoding has eliminated any risk of packaging errors; 100% read rates prevent incorrect tins being packed and print control has ensured the correct dates are applied. False line stoppages due to ‘no reads’ have been removed improving production performance.