Why Every F&B Manufacturer Needs Automated Packaging & Labelling Alongside Date Code Checks

As a responsible food and drink manufacturer, you understand the significance of delivering safe and trustworthy products to consumers. Customers trust your brand to give them safe, tasty products, and they want to know they can trust what's on the label. This is where automated packaging and label verification alongside date code checks play a crucial role, serving as your dedicated quality control team to guarantee perfection.

Why You Need Automated Packaging and Label Checks

When you're making hundreds, thousands, or even millions of items, it's hard to keep an eye on every single one. But your customers are counting on you to get it right. If a package goes out with the wrong label or missing information, it could be dangerous or even life-threatening to someone with allergies. Plus, if you're an own-label manufacturer, most retailers, including Marks and Spencer and Sainsbury’s, require a continuous online verification system.

With automated packaging and label verification system, you can check every single item you produce to make sure it's packaged and labelled correctly.

How OAL automated packaging and label verification works: We install cameras on your production line that scan every package. They check it against the job you're running and if something's not right, they'll stop the line so you can fix it. It's like having a second pair of eyes that never get tired or distracted.

The system stops the line and alarms if there is a fail-safe fault including:

Wrong packaging detected

Excessive no reads, product detected but no barcode found

Sensor failure

It's not just about safety and law either. If your products always look perfect and professional, it's good for your business. People are more likely to trust and buy from a brand that looks like they've got their act together.

Watch how the automated label verification works:

Why You Need Date Code Verification

Accurate date codes are equally crucial. They inform retailers and customers about the product's manufacturing and expiry dates, preventing early spoilage or unnecessary discarding of perfectly good stock. Incorrect date codes can tarnish your reputation and adversely affect your bottom line.

The good news is OAL has a system for this too. Our system configures your printers to ensure the accurate printing of date codes for each job, eliminating human errors like typos or incorrect printer settings.

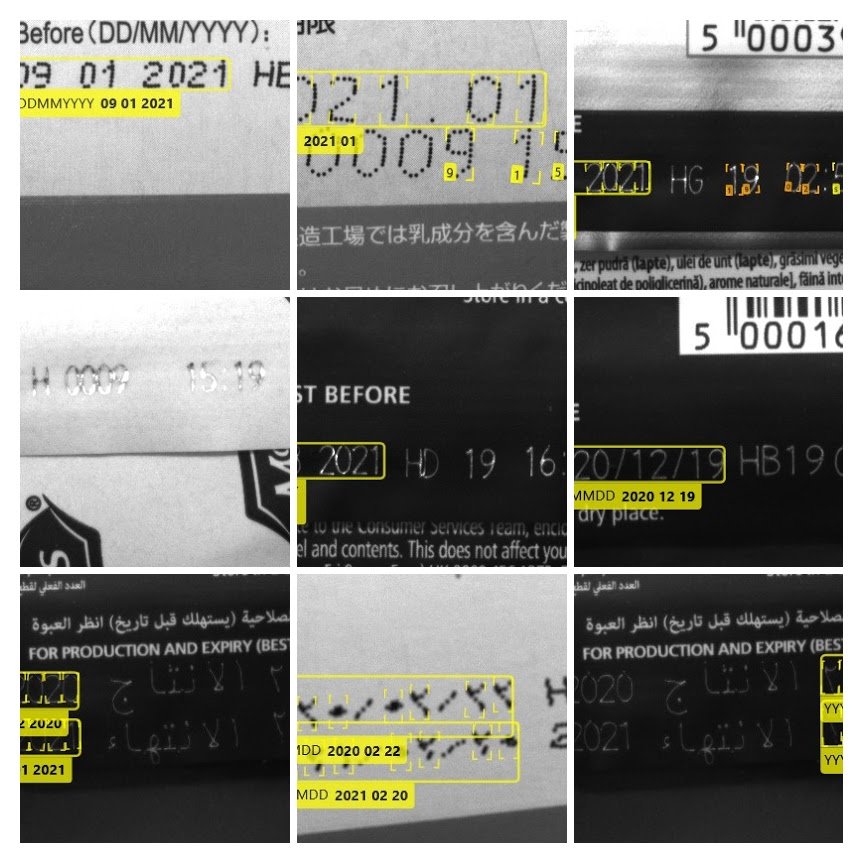

Our AI vision system, known as APRIL Eye, meticulously inspects every date code to ensure correctness and legibility. It adapts effortlessly to different fonts, sizes, and positions, showcasing its exceptional versatility.

Wrapping It Up

So, why do you need automated label and packaging verifications alongside date code checks? It's simple: to make sure your customers can trust your products, to follow the law, and to keep your products looking their best. It's all about taking pride in what you do and making sure you're delivering the best for your customers.

At the end of the day, OAL's systems are there to help you do just that. Need help? Let’s have a chat.