What is the best way to validate products and raw materials on the food production line?

If you supply major retailers like M&S, you’ll know that Brand Integrity and right-first-time production isn’t optional, it’s essential.

Across the UK and Europe, food manufacturers are being challenged to prove that the right ingredients and components are brought to the line, every time.

In this article, we’ll explain how leading manufacturers are validating products and raw materials, what technologies are used, and how to integrate this process into your packaging verification or autocoding system.

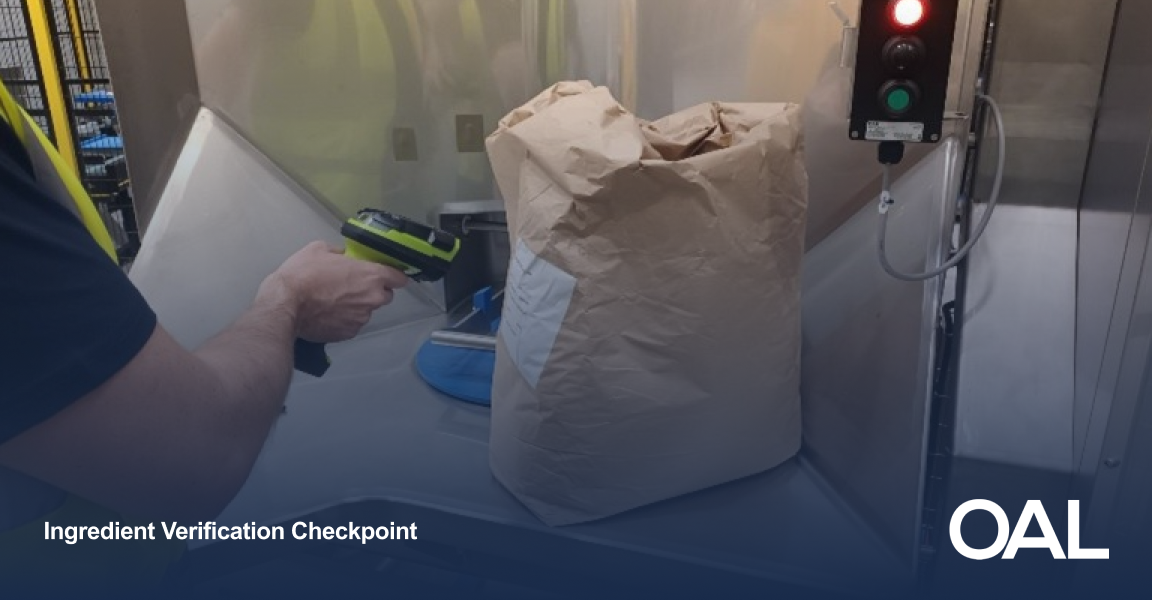

Validating incoming ingredients ensures the correct raw materials are approved before production begins.

Why validation matters

Every product, packaging or formulation error contains risk — from customer complaints, costly recalls, product rework to retailer delisting’s.

Validation is about one simple question:

“Can you prove throughout the chain of custody from the raw material to finished product that every Material, product and label is correct before production starts?”

Whether it’s the right flavour of crisps, the correct film for the product being packed, a correct legible date code, or allergen-free ingredients in a mix, the goal is the same: 100% assurance that what goes into the line is right.

Common problems we see

Food factories are facing a consistent set of challenges:

Frozen WIP product brought to the line for date coding without confirmation it matches the scheduled job.

Raw materials not validated against the active product record in the Autocoding or ERP system.

Wrong flavour or variant checks failing (e.g. sour cream & onion vs. cheese & onion crisps).

Limited barcode use — relying only on packaging scans, not raw material verification.

No automated link to ERP or BOM data, meaning operators can accidentally select the wrong component.

AI-driven inspection systems introducing uncertainty around allergens — good for detection, but not a replacement for validation.

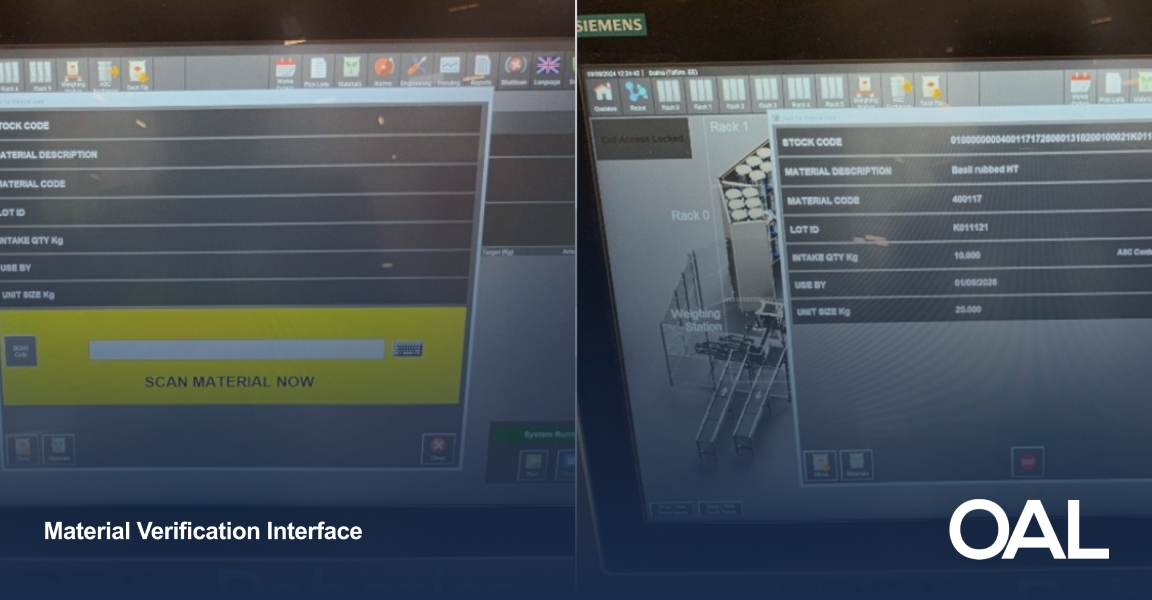

The Autocoding interface validates each material against the BOM before production begins.

Technologies that can help

1. Barcode validation

Simple and proven, each ingredient or component carries a 1D or 2D barcode that can be scanned before use.

An integrated system checks it against the active works order or Autocoding job.

Where possible, a decision tree can flag if a barcode isn’t recognised or doesn’t match the expected item.

For example, before a crisp line starts, the operator scans the flavour powder bag. If it’s not the correct flavour for the job, the line won’t start. That’s real validation.

2. RFID tracking

For higher-volume or bulk ingredient operations, RFID offers hands-free validation.

Each tote or container is tagged with an RFID label, automatically detected as it approaches the line.

At Jordan’s Ryvita, RFID tags were used to track fat additions into mixers — ensuring positive release before production could continue. It’s fast, reliable, and requires minimal manual input.

3. Vision inspection

AI-driven vision systems can complement barcode or RFID checks by verifying visual features — label type, colour, or even pack format.

However, for allergen-sensitive products, AI confidence levels matter. A 99% “likely correct” result isn’t enough when nuts are involved.

Vision can flag discrepancies, but validation should still rely on data-based confirmation (barcode, RFID, or ERP link) for full assurance.

Integrated validation workstations combine BOM checks, barcode/RFID scanning, and optional vision inspection.

The integrated solution

The most effective validation combines your Autocoding system, ERP, and factory devices into a single process.

When an operator selects a job in the packaging verification system:When an operator selects a job in the packaging verification system:

The BOM (Bill of Materials) for that product is automatically loaded from ERP.

Every ingredient or component is scanned (barcode or RFID).

The system confirms a match before allowing the line to start.

Optional vision cameras provide additional confirmation of the correct label, pack, or raw material container.

For example, in sausage manufacturing, operators scan meat batches and packaging components to verify they match the recipe and job number - all before mixing or packing begins.

At Premier Foods, Ashford, this approach was integrated with their ERP system to validate raw materials against the job selected in the Autocoding system.

The result: zero material mismatches and faster line changeovers.

Additional considerations

Retailer compliance: M&S and other major retailers now expect automated validation steps as part of packaging and traceability audits.

Allergen control: Vision and barcode validation should be paired with strict data rules — allergens cannot rely on probabilistic AI decisions.

Scalability: Validation systems can start simple (manual scans) and grow to include automated gateways or RFID tunnels as throughput increases.

Odio felis sagittis, morbi feugiat tortor vitae feugiat fusce aliquet. Nam elementum urna nisi aliquet erat dolor enim. Ornare id morbi eget ipsum. Aliquam senectus neque ut id eget consectetur dictum. Donec posuere pharetra odio consequat scelerisque et, nunc tortor.Nulla adipiscing erat a erat. Condimentum lorem posuere gravida enim posuere cursus diam.

Is it worth it?

For most food manufacturers, yes.

Adding raw material validation to your packaging verification system is one of the most effective ways to prevent recalls and build retailer confidence.

The time saved during changeovers and investigations alone often pays for the project within a year.

Next steps

Every factory is different.

If you’re exploring how to validate products and raw materials on your line:

Book a free demo with our team

Request a tailored quote

Learn more at an OAL Food Manufacturing Seminar

We’ll help you design a validation process that fits your site, integrates with your systems, and keeps your customers confident.

Related Posts

Lorem ipsum dolor sit amet, consectetur adipiscing elit.