Top 10 AI Verification Quality Checks for Food Packaging

AI is changing how food manufacturers manage quality and compliance. For years, packaging checks relied on human inspection, often limited by speed and fatigue.

Today, AI vision systems perform these checks faster and more reliably, spotting missing components, incorrect labels and even allergens in real time.

Here we take a look at our top 10 verification checks, where AI cameras can help you.

AI and camera technology — the quality game changer

Original 1D barcode verification in 2001

For decades, the quality control of packaging and labelling has been a manual task, reliant on human attention to detail and often a factor that slows down the speed of the production line.

In 2001, we introduced the first barcode verification system with Tesco and Bakkavor.

In 2019 we introduced APRIL Eye, the world’s first AI-based date code verification system.

Prior to that there had been a reluctance as OCR vision couldn’t handle the variation of the fast-moving food industry.

By combining AI with vision camera technology, the game has changed. The best way to understand the impact that AI-powered cameras can have on packaging and labelling quality assurance is through real-life use cases.

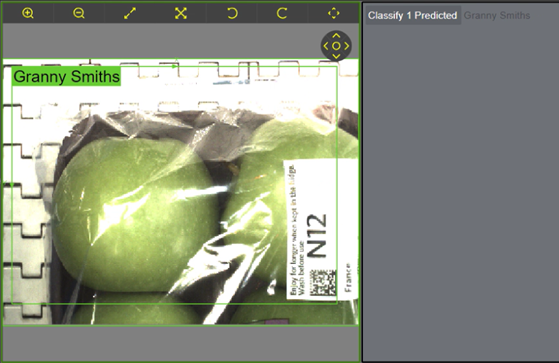

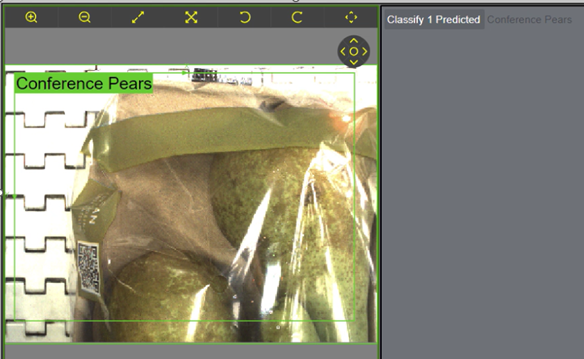

1) That’s not an apple!

The worst nightmare - an item placed in the wrong packaging. AI-powered cameras are able to see beyond clear packaging and recognise the items inside. Is the item in the apple packaging actually apples? Or are they pears?; or maybe even the wrong type of apples? – the AI-powered camera can spot this.

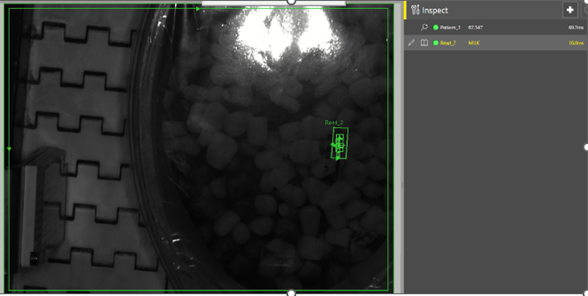

2) Where are my croutons?

When there are multiple components required to be placed inside the packaging, a key quality step is to ensure that everything is included.

Verify the presence of components like croutons in bags of salad.

3) I can’t eat that without a fork

You’re packing a meal kit; has everything been included?

Verify the presence of objects like forks and spoons.

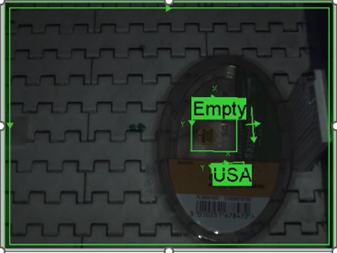

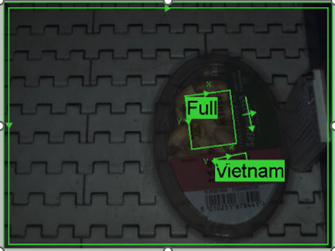

4) Where were these made?

Read and verify printed text on the packaging.

Check the country of origin matches the works order.

Conduct multiple checks simultaneously to include the presence of the finished product.

6) Are we on promo?

An AI camera can check the presence and content of a promo label.

7) Check allergens on WIP product

Ensure WIP product brought to the packaging line is correct by reading the printed information on the film.

8) Is the lid on tight?

With AI, you can verify every product to ensure rare events like bad lidding is caught in the factory.

9) Is the seal intact?

Verify the seal integrity of finished products using AI cameras.

10) Italian or cheesy?

The label on the bread says “Italian”, but is it really? Checking that the right type of bread is in the correct packaging with the right label is another great example.

Leveraging AI To Make A Big Impact

These are just some of the areas where AI-powered cameras and packaging and label verification solutions are having a big impact on food manufacturing. Yet this is only scratching the surface of what is now possible.

Have you considered ERP integration? By integrating your ERP with line devices you can make the most of AI to ensure your business is running off one single source of truth.

We can help analyse your process to understand the impact AI cameras can have on your quality. If you would like to discuss any of the use cases please do get in touch.

The next generation of packaging verification combines OAL’s Connected software with AI vision systems like APRIL Eye, giving manufacturers full confidence in product quality and compliance.