Online label printing - save money and reduce downtime

In many food facilities, there’s no doubt that offline printing seems convenient, but it can often be problematic. With numerous grower codes, batch sequences and use-by dates to be printed on to individual labels along with the retailer specifications for each SKU, there’s a lot of potential for error. What’s more, the changeover process itself can result in a significant amount of downtime - reducing your efficiency and costing you money. With so many deadlines and volumes to meet, manufacturers just can’t afford these losses. But what if we said you could increase efficiency, minimise downtime and even achieve up to 20% labour cost savings a year, all by printing your labels online?

Minimise downtime

Downtime in some form feels like an inevitability on the packaging line. Whether incurred through initial start-up checks or time spent waiting during a multi-line label changeover, downtime can steadily build. But it doesn’t have to be this way.

You may not have considered it but offline printing is a major cause of downtime. If all of your labels are printed centrally rather than directly on the line, your product runs could be stopped for up to 15 minutes at each changeover while the line is emptied and the next batch of labels is collected and loaded into the line. Once you factor in this stoppage on each of your lines at every product changeover every day... you can see how the downtime builds up, impacting your volumes and increasing your labour costs as your operators have nothing to do for hours each day. For example, if you’re running 80 SKUs on 10 lines, an average changeover of 15 minutes could be costing you up to 20 hours in downtime a day.

Yet with an automated system controlling your printer, you could seamlessly print your labels online and apply them directly to your products, with the right label and information at each changeover. No more downtime between products, increasing your productivity and allowing you to reduce headcount on your line, resulting in up to 20% of annual labour savings.

Reduce waste

By printing labels in real-time, you can reduce the amount of waste from labels printed in advance, as we find that most manufacturers generally over-print to ensure that they have enough to cover each product run. If you consider that you may print 500 additional labels ‘just in case’ with each product run for each line each day, the waste soon adds up. And that’s not even taking into account the waste generated when the wrong label is printed. By printing your labels directly on the line, you can save money on materials in the longer term, as well as helping to contribute to your company’s green initiatives.

Improve accuracy

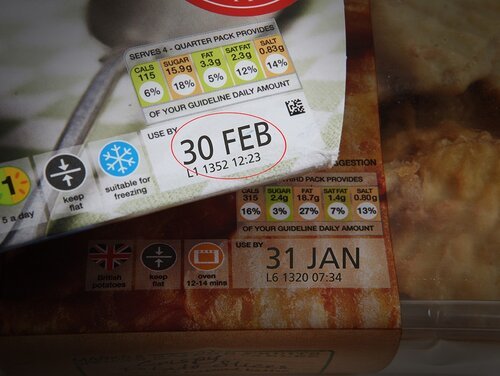

While the idea of increased productivity and reduced costs and waste is undoubtedly appealing, you may worry about the accuracy of real-time label printing. After all, the last thing you want is a product recall due to incorrect product labelling. That’s where a robust label & date code verification system comes in. Our original Autocoding solution controls the printer to ensure the right information is printed, and then as a final step, our scanners will check that the information on the pack matches the job set up for the line.

For optimal results, we recommend customers use 2D barcodes as they are able to store the batch code, grower number, use-by date and much more in one small area that can be easily read by our system. All of the information is set up by the Technical team so the operators on the line are removed from the process. In this way, our system acts as the final kill step, identifying what the date code is and matching it back to the product run information, rather than just checking that it matches the date put into the printer by the operator, giving you peace of mind that the right product with the right packaging will reach your customers.