Olympus Automation dominates Food Processing Awards

Olympus Automation were nominated for 4 Awards at the 2013 Food Processing Awards and had success in all, including a WIN for our excellent Autocoding product. The dominance of the event was picked up by the after dinner comedian, Hardeep Singh Kohli, who continued to push the Olympus Automation name during his set. Everyone who attended certainly knew a lot more about Olympus Automation at the end of a very successful evening. Click here for the full Food Processing review of the awards ceremony.

Will 3D factory scanning improve food factories?

3D scanning is used extensively for industrial design and in the production of movies and video games but does it have value for use in the food factory? In the ideal world every factory would have accurate, fully dimensioned, 2D/3D drawings of every part of the facility so that new plant modifications can be easily designed. Whilst this will be in place for new plants, at OAL Group we have found in most cases the first step for plant remodeling, is a time consuming measurement and drawing process.

For complex plants this takes too long and it can be difficult to attain high levels of accuracy. This lack of visibility often means that initial discussions of new layouts, at a senior level, are delayed or made worse by relying on inaccurate layouts.

How does 3D scanning work?

The most common scanners for this purpose are tripod based with a rotating scanner and camera, with the camera there to colour the scan points. The laser scanner uses phase shift to measure the distance between points from the scanner location. At each position the scanner captures hundreds of thousands of measurement points per second in a full 360° data capture, creating a complete sphere pattern of dot positions. As equipment within the room obscures the scanning process multiple scans from different position are required to obtain information about all sides of the area contents.

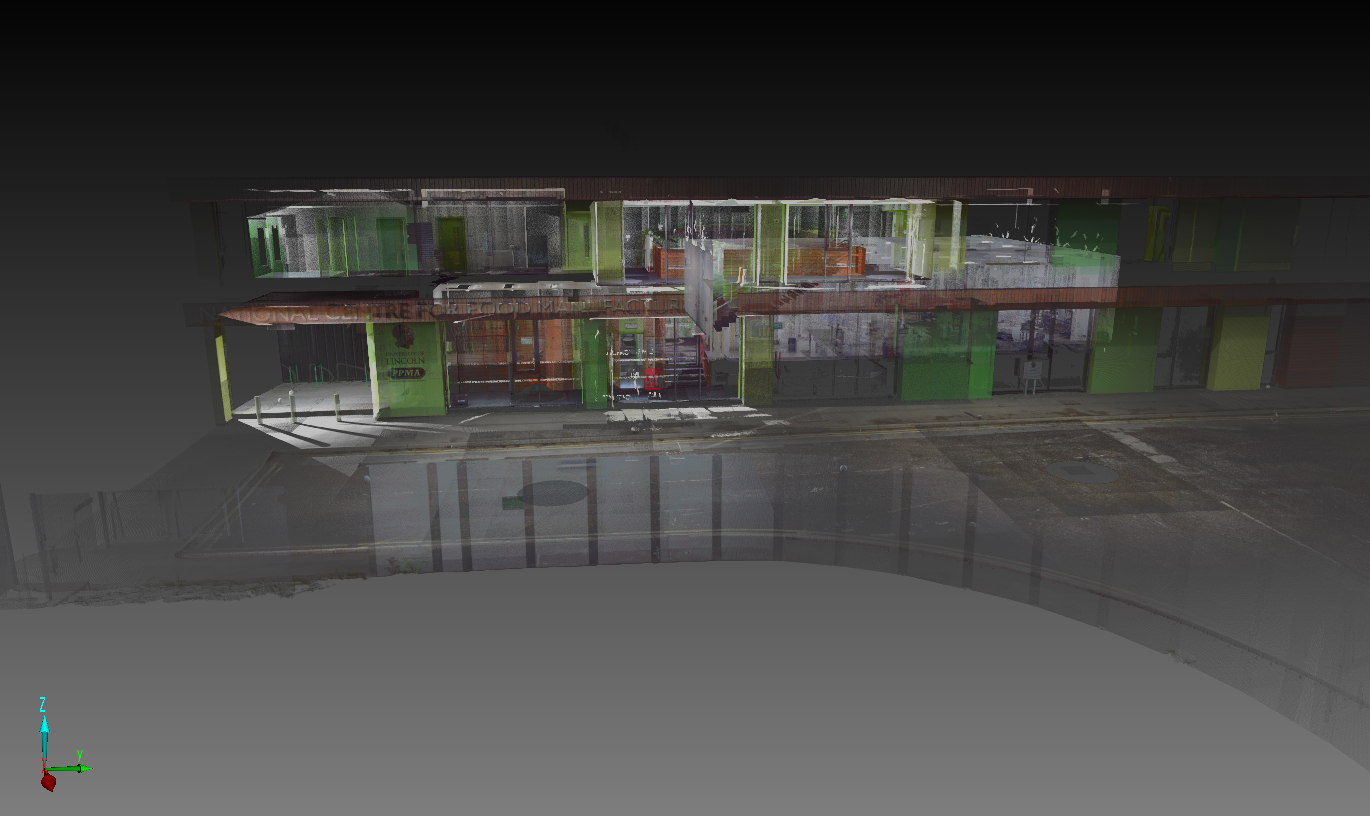

Once multiple scans for a single area are complete post processing stitches together millions of data elements into a ‘point cloud.’ The process is then repeated for other factory areas with post processing including joining individual ‘point clouds’ together creating a ‘project point cloud’ of the entire site.

The outcome

The results of the process permits a 3D ‘walk through’ of ‘as installed’ plant to a measured accuracy of up to 2 mm, with the ability to dimension and add annotations to any 3D element. That means plant remodeling is based on accurate data making the design process much quicker. It also means that reverse engineering of assets and components is possible. Whilst 3D CAD uses are likely to have powerful workstations to access the files, standard users are supported by a secure web application allowing unlimited views within the organization on standard desktop pcs.

The accuracy is so good that at a recent exhibition many visitors thought the 3D scanned images where videos until they were shown how to ‘walk-through’ and measure elements.

3D scan to CAD is twelve times faster than manual measurement

Applications in the factory

Whilst 3D scanning for video games and the entertainment industry may be exotic, there are many uses that could be considered for factory use with implications across a number of key disciplines in the industry.

Import to 3D CAD

This is probably the most obvious requirement for project engineering and maintenance teams. The 3D scan to CAD process is twelve times faster compared to manual measurement with much higher accuracy rates. The point clouds are imported into software that sections the point cloud and uses the points to create geometry, a bit like tracing in 3D. The days of tape measure, paper and camera to create CAD layouts must surely be coming to an end.

The three step process of 3D scan - Point cloud - 3D Cad means that by step 2 the 3D walk-through and ability to dimension and annotate is available within a few hours. That means benefits are gained whilst work continues on the final step, the import to 3D Cad for further design work.

It is estimated that, whilst import to CAD is important, a much as 60% of the benefit for the factory team could be gained once the point cloud has been created at step 2.

Supplier review

Want a potential supplier to quote for plant modifications but don’t want him to see the full site? Don’t have time for the supplier to arrange a site visit? Give him secure web access to a restricted part of the plant from his own location. The ability to walk-through and dimension allows both parties to view simultaneously and compare ideas and thoughts on line. That allows more potential suppliers to be involved and reduces the time to project quotation.

Reverse engineering

Have failed asset components from obsolete equipment, or missing CAD files from an old project? Use 3D scanning to quickly digitise a part and create a fully surfaced CAD model which can then be used to reproduce a local copy. There is no effective limit in terms of size, with larger and more complicated items just needing more scans.

Plant reviews

The regional management team wants to quickly review plant layouts. Of course a ‘Genba or Gemba’ visit to the manufacturing floor is better but for an initial check or quick safety review a 3D walk-through will be quicker and much more realistic. The ability to dimension also means that initial assessments can be made to see if the new kit could possibly fit in that position.

Asset register

Creating an asset register from scratch takes a long time and it’s not unusual for the process to take months. Whilst a 3D scan won’t identify the plant nameplates or serial numbers it’s a great start and will speed up the equipment identification process. Database links can be made in both directions with the 3D scan point cloud able to load an asset register and the asset register, in turn, able to load the 3D scan point. The is no reason why the process cannot be part of maintenance checks with the inspection content linked to, and taking the engineering to, a precise location in the 3D scan point cloud for a physical review.

Incident investigation

One final application you may hope not to use. Forensic crash investigation allows data to be recorded for office based analysis and supports vehicle deformation comparison against standard measurements. Could those techniques be used for industrial incidents, almost certainly?

Being able to walk-through an accurate 3D layout increases plant visibility significantly, it’s as close as you can get to being there in the room. The tools are here to stay with more uses being identified daily. Try it out and you'll wonder how you managed without it.