Worldwide Fruit, UK - Stopping human error with automated product label verification

Worldwide Fruit is a growing £200+ million turnover fruit marketing and distribution business. Quality is critical to their customers, and they wanted a solution that could scale across their complex operations handling thousands of SKUs from over 1,000 global growers. OAL has helped Worldwide Fruit automate to ensure all its products have the right date code, right packaging and country of origin.

Worldwide Fruit is a growing £200+ million turnover fruit marketing and distribution business. Quality is critical to their customers, and they wanted a solution that could scale across their complex operations handling thousands of SKUs from over 1,000 global growers. OAL has helped Worldwide Fruit automate to ensure all its products have the right date code, right packaging and country of origin.

UPDATE: Worldwide Fruit is on a SMART Industry journey supported by OAL. The first phase deployed label and date code verification to ensure the right-first-time packaging and date coding in 2020, including the use of AI vision checks with APRIL Eye.

In the second phase in 2023, OAL has helped Worldwide Fruit seamlessly integrate their ERP (Prophet), Label and Date Code Verification (OAL), and OEE (Redzone) systems.

Challenge

The right apple must be in the right packaging with the right date code and country of origin.

Ensuring the highest standards of quality control and food safety are mission-critical priorities for Worldwide Fruit. Previously manual human checks of product labels, date code and country of origin were undertaken, but these methods are susceptible to human error, especially in a high-complexity business.

Complexity to Worldwide Fruit is driven by the different product, grower, and packaging combinations. For one category like apples, there are many varieties of apples from different countries with different packaging and promotion requirements from each retailer.

For a production run, Worldwide Fruit must ensure the right product (apple), is in the right packaging with the right date code and country of origin. Any mistake in the process could result in a product recall and a fine from retailers. To address these challenges Worldwide Fruit turned to automation.

Solution

Phase 1: Label and date code verification - 2020

After a review of suppliers, Worldwide Fruit chose to work with OAL because of recommendations and previous experience implementing the OAL system. Furthermore, they wanted to work with a business that could integrate with their existing ERP system, which OAL could demonstrate.

The priority was implementing an “online” label and verification system across its 16 packaging lines to accelerate its digital transformation. Online meaning, every product is verified as opposed to “offline” where a sample is verified.

“The team at OAL are easy to work with, working together we have implemented a robust automated label and date code verification system. By introducing cutting edge artificial intelligence technology we’ve futureproofed our packaging lines, enabling further automation. Crucially we’ve been able to customise the system to meet our unique requirements. The 24/7 support is quick, friendly, and efficient!”

First, a master product database was installed on a site-based SQL server. This is a database managed by the technical team that stores all product information. OAL’s ex-industry trainers assisted WWF in populating the database.

The OAL system was installed and commissioned comprising:

OAL Line Terminals on every line for operators to start and finish jobs and conduct quality checks related to the job.

Cameras to scan and verify packaging to ensure the right packaging is applied to the product.

Each online printer was connected to the OAL system. The OAL system controls the printer and tells it the date code to print based on the date code rules in the master product database.

The offline print room printers were also under the control of the OAL system to ensure offline printed labels were also correct.

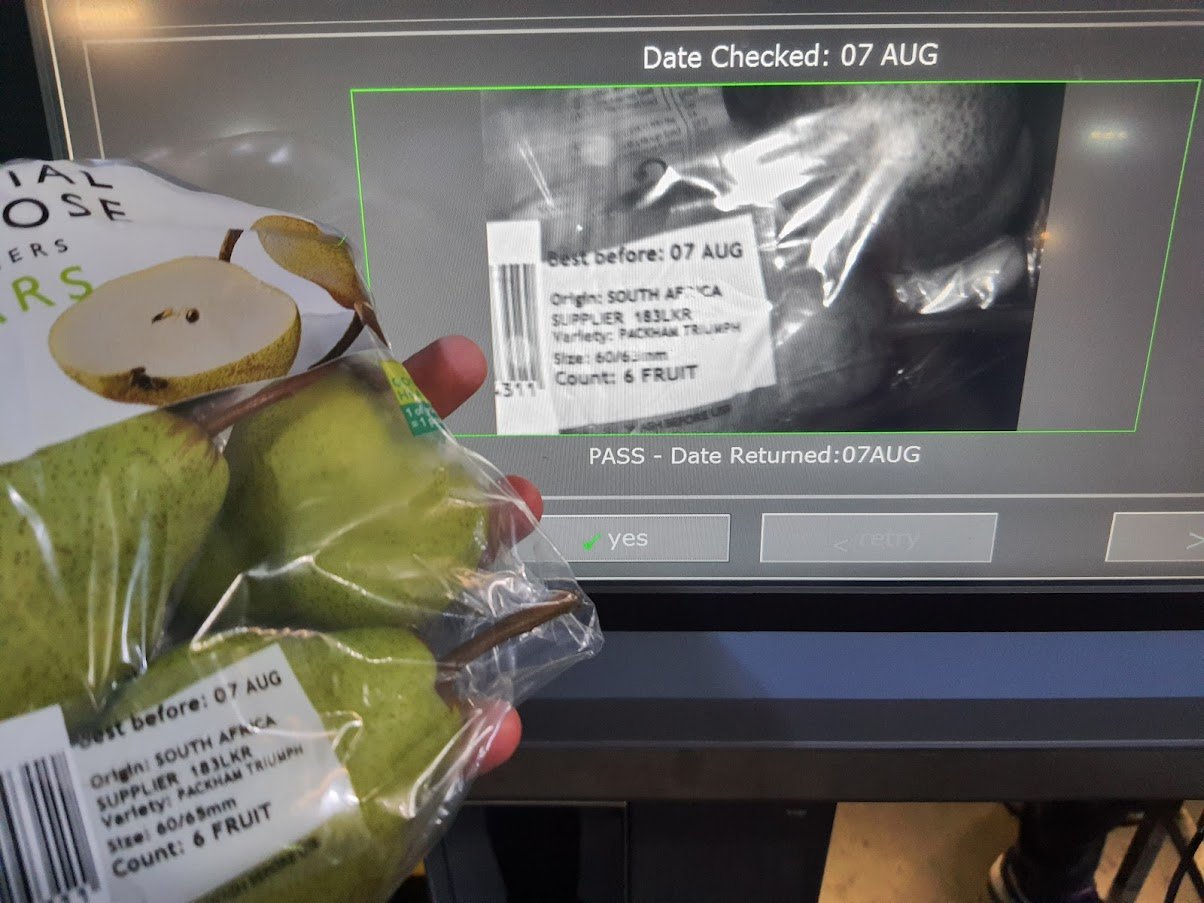

Finally, the site chose to add an extra layer of assurance with APRIL Eye date code verification. APRIL Eye gives the OAL system the functionality to read back and verify printed date codes in an image. This ensures the right date code is applied, it’s legible and in the right location.

At Worldwide Fruit, as part of start-up, interval and end-of-run checks the operator takes a picture of a finished pack with the OAL line terminal hand scanner. The system checks it’s correct and legible against the current job.

Finally, every check, scan and data point is recorded providing a complete digital audit trail to ensure BRC and retailer code of practice compliance.

OAL provide a 24/7 support contract to minimise downtime and ensure the system is functioning to specification.

Phase 2: ERP and Redzone Integration - 2023

Worldwide Fruit had a long-term vision to automate and digitalise its packhouse to ensure the right data first time. OAL utilised the Ignition SCADA/MES Platform to integrate the different business systems driven by works orders generated in Prophet.

The user experience is:

Job scheduled in Prophet

Job appears for selection on the OAL Line Terminal as a works order

Job selection by operator on the OAL Line Terminal sets up cameras, printers and starts a job in Redzone.

“Working with OAL on this project has been great for managing complexity and automating several ERP tasks with the Ignition MES. OAL has made it easy to ensure right-first-time data by integrating Prophet with Redzone and Autocoding applications. We are looking forward to uncovering more opportunities together in the future.”

Key results

Worldwide Fruit has scaled and improved its quality control processes, resulting in happier customers and reduced operational risk. Automation has helped find and prevent “hard to spot errors” whilst reducing the time it takes to complete quality control checks. They have also removed substantial paperwork from the business helping meet and surpass sustainability goals.

The 2023 system integration project has created a single source of truth for Worldwide Fruit helping them make critical business decision based on accurate, real-time data. This integration has resulted in Worldwide Fruit’s SMART Industry Ready Index rank being better than ever and closer to their SMART Industry roadmap.

You can automate and digitalise your operations - speak to our team today for advice and guidance.

At a glance

Customer since: 2020

Challenge

Complex operations with thousands of SKUs

Improve quality control and labelling

Future ERP integration capability

Solution

OAL Connected with Autocoding, Paperless and APRIL Eye functionality.

24/7 support with annual audits to ensure code of practice compliance

Integration with Prophet ERP and Redzone OEE using Ignition SCADA/MES

Results

Improved quality control through an automated system

Deployed AI-based verification to enable further automation

Improved sustainability by removing paperwork

Right first-time data from a single source

Wealmoor, UK - Improving Quality with Automation

Wealmoor has built a reputation for specialty fruit and vegetables, supplying high-volume, high-quality produce every week. Across their UK factories, they have automated their date coding and packaging processes with the OAL Connected system including Autocoding and APRIL Eye functionality. Going digital has enabled them to eliminate product packaging and quality issues and significantly reduce food waste.

Wealmoor has built a reputation for specialty fruit and vegetables, supplying high-volume, high-quality produce every week. Across their UK factories, they have automated their date coding and packaging processes with the OAL Connected system. Going digital has enabled them to eliminate product packaging and quality issues and significantly reduce food waste.

Background

Wealmoor is an established, family-owned business specialising in the growing, packing and marketing of subtropical fresh fruits and vegetables from all over the world. They also produce homegrown seasonal vegetables and herbs.

In 2020, the company began investigating ways to help reduce food waste, product recalls, and complaints by transforming their operations. In particular, product packaging and quality errors in the packhouse were identified as a key area of improvement.

Challenge

Like many fresh produce companies, Wealmoor’s packaging processes were manual and paper-based. Use by dates were being manually adjusted on the printer by an operative checking against a printed reference document, which on occasion resulted in date errors. Shelf life could also be calculated for longer than intended. Possibility of these errors could result in product recalls, damaging company reputation and customer confidence whilst also being very costly.

Furthermore, batch processing was difficult as many products had to comply with a range of different customer requirements. For example, one product had over 40 different SKUs, making it difficult under a multi-tasked, constant pressure environment for line leaders to determine if a product was in the wrong packaging easily. As a result, both products and energy could be wasted.

Finally, Wealmoor’s offline print room was using an end-of-life label design software called Dataguard, which needed to be replaced with an integrated solution for label management.

Solution

Wealmoor chose to implement the OAL Connected system with Autocoding, Paperless and APRIL Eye functionality within their UK factories. These systems allowed them to both digitalise and integrate their systems to reduce manual errors. The controlled and centralised technical database that OAL Connected provided removed a large amount of paperwork whilst also ensuring that customer specifications were correctly adhered to every time.

By implementing the Autocoding and APRIL Eye modules, operational quality control was significantly enhanced. The system ensured that date codes and shelf life were correct and accurate, preventing production errors, rework and product wastage. Structured quality control testing regimes were put in place, which could be tailored to different customer specifications. In addition, a system was introduced that would check for errors and automatically stop the line before production was significantly affected. This made packaging, film, and ingredient errors much less likely.

The OAL solution automated online and offline label printing, replacing the existing Dataguard & Vector label design software with Clarisoft. For operators, this resulted in a streamlined user experience as they use one system for both online and offline printing.

“The introduction of automated systems from OAL has completely changed our operations. Since its installation, we’ve been able to streamline our processes and prevent errors before they caused further issues, protecting our reputation, enhancing trust and confidence. We’ve also seen the significant opportunity in increasing efficiency and operational effectiveness.”

Key results

The new system has prevented human error such as incorrect film application, packaging issues, and incorrect dates and barcodes in the packhouse. As a result, operational downtime has been minimised and wastage and product recalls have been prevented. In turn, this has helped the company protect their reputation and drive sustainability.

A further benefit of digitalising their systems is that is has allowed Wealmoor to upskill their staff and improve employee engagement and retention.

Transitioning to an integrated, automated system doesn’t have to be difficult – speak to one of our team for expert advice and guidance.

At a glance

Customer since: 2021

Challenge

Automate and digitalise existing paper-based processes

Reduce food and energy waste caused by date and coding errors

Improve quality control and correct labelling

Solution

OAL Connected with Autocoding, Paperless and APRIL Eye functionality.

Implemented a controlled, centralised, digital technical database.

Introduced structured quality control testing regimes tailored to customer specifications.

Results

100% compliance with customer requirements.

Reduced energy and food waste through fewer production errors.

Improved quality control through automated system.