Automate Palletising in Food Manufacturing

Boost throughput, reduce labour and maximise floor space with OAL palletising robots. Designed for food and beverage manufacturers, our compact fenceless palletisers run up to 3x faster than collaborative robots and are ideal for space-restricted packing halls.

Save factory space with a compact, fenceless design

Keep staff safe and remove ergonomic risk

Run at high production speeds (up to 30 cases per hour)

Integrate quickly with your existing lines

Achieve vertical start-up following FAT at OAL

Automation trusted on 2,000+ food production lines

Find your Palletising Solution

Select your packaging type, production rate and space to identify the best palletising configuration for your site.

Select packaging type – Boxes, Open boxes, Crates

Select number of packs per minute – 20 to 180 (increments of 60, 100, 140, 180)

Input smallest case size (minimum 2)

Choose sector – Fresh produce, Prepared food, Meat & seafood, Other

Do you have a lot of space? Yes / No

Recommendation is based on

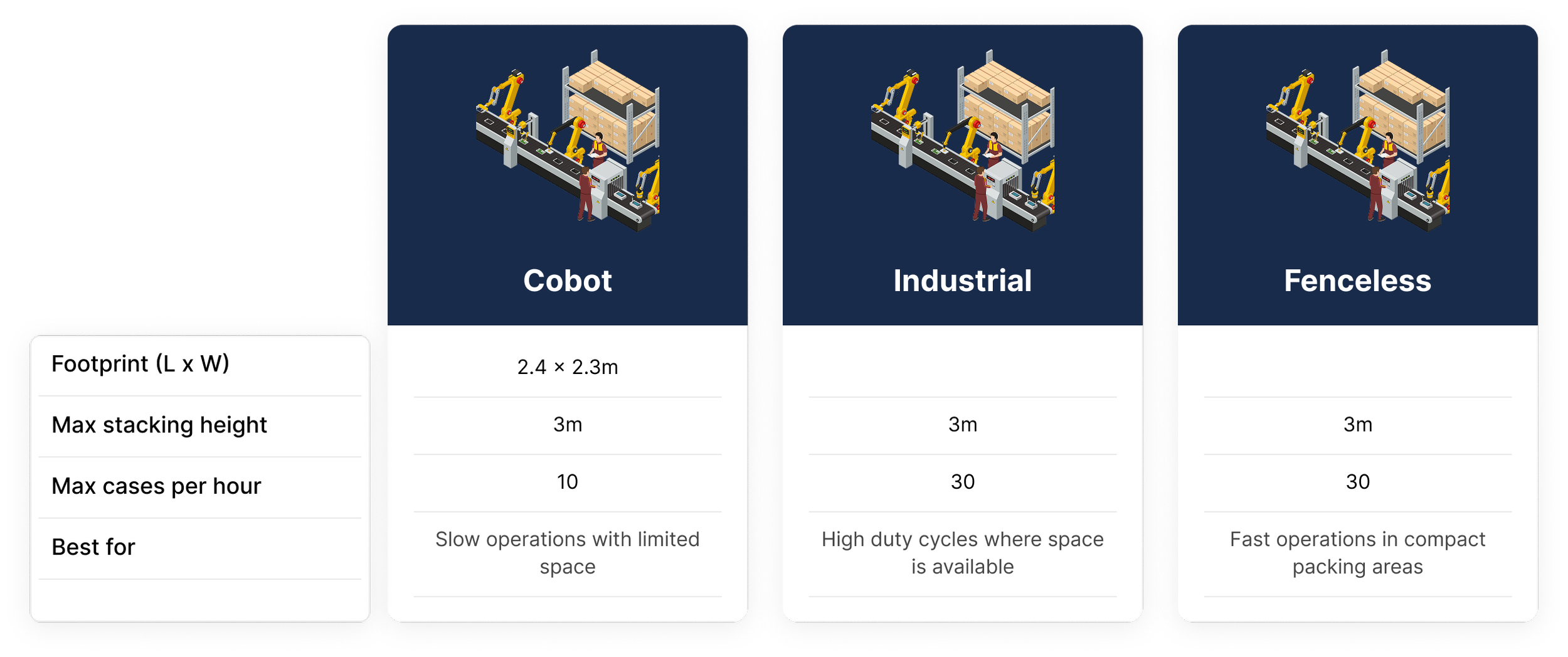

Cobot palletiser – essential automation

Ideal for lower-speed lines replacing manual lifting. Delivers consistent, reliable stacking with a compact footprint.

Benefits: Quick installation, no fencing required, easily moved between lines.

Industrial palletiser – maximum throughput

For high-output lines or heavier products. Built for continuous operation and full integration with conveyors and line controls.

Benefits: High payload capacity, multiple stacking patterns, proven reliability.

Fenceless palletiser – high speed, small footprint

Combines industrial performance with collaborative safety. Torque sensors and zone monitoring remove the need for cages while maintaining high speed.

Benefits: Compact, compliant, integrated and ideal for multi-SKU, fast-change environments.

Choose the Right Palletising Configuration

Food factories vary in speed, space and packaging types. OAL offers three standard palletising systems, each proven for compliance, safety and flexibility.

Fenceless Automation Built for Food Factories

Compact Footprint

Up to 10× smaller than traditional robot cells, ideal for space - limited packing halls.

Fenceless Operation

Certified to PLe / ISO 13849, designed to work safely alongside your team.

High Production Speed

Up to 3× faster than collaborative robots while maintaining full compliance.

Food Industry ready

Hygienic and robust, suitable for chilled, ambient, and fresh produce environments.

Managed Service Support

Performance SLAs, 24/7 remote access, and nationwide engineer coverage.

Frequently Asked Questions

Answers to the most common questions you might have.

-

A palletising robot automatically stacks cases, boxes or crates onto pallets at the end of a production line. OAL’s systems are designed for food factories where hygiene, safety and space are critical.

-

No. OAL’s fenceless system uses safety-rated torque sensors and laser area monitoring to remove the need for cages in most applications.

-

Yes. Each palletiser can be fitted with grippers or vacuum tooling to handle open-top or variable packaging types.

-

Most systems are installed and running within 2 to 3 days, following pre-tested FAT at OAL.

-

Yes. OAL offers finance and leasing options with managed service SLAs, helping you spread the cost while guaranteeing uptime.

-

Yes. All robots and enclosures can be supplied in stainless-steel or washdown-rated finishes for hygienic environments.

-

By automating manual palletising, OAL systems reduce headcount by one operator per shift, increase throughput and remove ergonomic risk while maintaining consistent pallet quality.

Let's get in touch and work together!

Find your palletising solution or book a demo at OAL’s test centre.

+44 1733 394700

A1 Parkway Peterborough, PE2 6YN, United Kingdom

sales@oalgroup.com

Automation without barriers

© Copyright | 2025 OAL Group, LLC