Harry Norman's top 4 tips to thrive in 2020

With almost 30 years working with the food industry, Harry Norman’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

During the current climate of uncertainty, it’s clear that food manufacturers are up against it. Having to meet increased demand with fewer people while also implementing social distancing measures to protect staff and at the same time working with equipment that has perhaps seen better days… It’s certainly been a hard few months and it’s likely to continue. As reported in The Times, analysts at Peel Hunt have calculated that £23 billion has been cut from CAPEX budgets for this year in British listed companies alone. This means that it could be some time before manufacturers can consider investing in new machinery, let alone innovations to take operations to the next level.

It’s now more important than ever to make the most of what you have, something that our MD, Harry Norman, knows plenty about. With almost 30 years working with the food industry, he’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

Digital transformation

Productivity has always been the key buzzword in the global economy, but it has perhaps never been more necessary to return to pre-2008 levels. It was reported in February 2020 that the slowdown in productivity growth in the UK over the last ten years is the worst since the start of the Industrial Revolution 250 years ago, and the impact of COVID-19 is likely to have only worsened this situation.

So the question is, how can you increase your productivity, particularly if you can’t invest in major capital equipment? One way is to begin your journey towards digital transformation. By digitising your operations, you can typically achieve productivity savings of 10% running smarter and leaner and making the most of your existing assets. For example, by going paperless, your plant data can be transformed into useful insights, rather than disparate sheets of paper, allowing you to identify bottlenecks, downtime issues and waste. Our experts, trained in Six Sigma, alongside our software such as our LMS or APRIL Eye, can help you drive productivity gains across your entire facility.

Process simplification

Total production time for three 1,000 kg (2204 lb) batches of béchamel sauce using a traditional steam jacketed kettle vs. Steam Infusion.

When was the last time you reviewed your processes? We mean really delved into the detail? Chances are, it’s been a while and you could benefit from a fresh set of eyes highlighting any simplifications or rationalisations that can be made to speed up operations and boost efficiency. OAL is 100% dedicated to the food industry, and having completed hundreds of projects for manufacturers, both big and small, it means our experts can look at things differently, saving our customers millions of pounds through simple changes to improve throughput.

For example, one of the ways in which we can reduce the processing time of a béchamel sauce is by using our award-winning Steam Infusion technology, which not only achieves faster cooking times but also reduces the number of processing stages required. The traditional roux is not needed at the beginning of the process, and Steam Infusion can be used to mix whilst heating, while the lack of burn-on means that the number of CIP cycles can be reduced by up to 80%, saving valuable time and money.

Focus on maintenance

There’s no doubt that as people, we’re all more interested in innovation than maintenance, and it’s no different when it comes to plant equipment. But while budgets are tightened, it will become vital to make the most of your existing kit. It might be tempting to reduce maintenance right now but while you may see short-term gains, you could see long-term damage. An effective maintenance schedule and working with experts can help to take care of your kit to help it last longer.

For example, our Steam Infusion technology can also be used to extend vessel life. There’s no need to condemn your kettle cooking system and invest in a new jacket or tank if it fails the pressure tests or is no longer cooking efficiently. A simple retrofit adding one of our In-Tank Steam Infusion Vaction Pumps breathes new life into your existing kit, while delivering added benefits such as near maintenance-free operation and energy efficiency – particularly valuable at this time.

Consider used equipment

As we see the unfortunate news that some plants are closing due to the challenging economic conditions, we will inevitably see a rise in used kit coming on to the market, and this will be of a better quality that can usually be found. This can often be a cost-effective way to boost your productivity but it can be a challenge to find the right equipment and ensure that it is installed seamlessly into your existing processes.

While used kit can often represent a bargain, it requires a diverse set of engineering resources to integrate equipment that doesn’t meet your exact requirements. It may look great on paper but there are a number of questions to consider, such as how old is it, what is the warranty, are the controls current and even how will you get it to your plant?

Working with trusted partners, such as OAL, who have experience in delivering both new and refurbished equipment, as well as effective maintenance, ensures you get the right advice before committing, allowing you to minimise the risk and maximise savings.

Get in touch today to see how we can support you during this time!

Harry Norman's predictions for 2020

As we gear up for another busy year and the start of a new decade, Harry Norman, our founder, reveals his top trends for 2020.

As we look to the start of a new decade, we’re taking some time to speak with our founder, Harry Norman, to discuss what he thinks are the key trends in 2020.

Harry, what are your top trends for 2020?

I think main focus in the food industry in 2020 is a continued focus on improving productivity. This will be achieved through a variety of initiatives as well as the growth in adoption of tools like robotics and machine learning.

It seems like productivity is a permanent concern for food & beverage manufacturers. How can they make a material difference to their productivity levels in 2020?

Productivity has been a major concern for businesses around the world for over a decade but we don’t seem to be able to find the right answer. Latest figures from the ONS showed that productivity in the UK fell at its fastest annual pace in five years in during the April-to-June quarter of 2019, so arguably the problem is getting worse rather than better. Productivity in the food industry has been dropping due to increased product complexity, which requires more production staff to achieve the same volume. This has also led to further erosion of margin as labour costs continue to increase. In April 2019 the national living wage for those aged 25 and over in the UK increased by 4.9%, from £7.83 to £8.21, and it’s set to rise further. The same trend can be seen across the globe so manufacturers need to think outside the box in terms of their productivity.

We know that this is a real priority for our customers but we find that the solution is often in overlooked areas of manufacturers’ operations and that small savings can really add up. For example, if you’re carrying out offline printing on your packaging line, the time taken for a changeover for a new supplier code can quickly mount up. We’ve been able to save customers typically 1-2% of line manning hours by automating the changeover, allowing them to increase production time and reduce labour costs as fewer personnel are needed on the line. By working with experts to review their operations, food manufacturers can find many examples like this and boost their productivity levels by increasing efficiencies.

Robots are another way for manufacturers to boost their productivity – do you think adoption in the food industry will grow in 2020?

Absolutely! As an industry we have generally been slower to adopt robotics than others such as automotive. But the barriers are starting to be broken down and we’ve already seen growth of 50% in robot adoption over the past five years, primarily due to retailer pressure for larger volumes at lower prices combined with consumer demand for safer and more sustainable production. However, we know that this growth has primarily been driven by robotics on the packaging line. I believe that 2020 will be the year that we achieve significant growth in robotics upstream in the processing stage of food and beverage production.

In 2018, we began to see reference sites piloting our robotics technology, and now as we enter 2020 this technology is really taking off. Food and beverage manufacturers are eager to take advantage of the proven results that APRIL Robotics can bring. Our robot chef and automated ingredient handling system allow manufacturers to move to unmanned production, boosting productivity, cutting labour costs and improving product safety – three priorities for manufacturers all over the world. We’re able to achieve payback within two years on our systems so automation of your processing stages needn’t be a pipe dream!

Closely related to robotics is the trend of machine learning. What do you think the impact of this technology will be on the industry?

Machine learning has the potential to transform the food industry. Many companies in Asia have already adopted AI in their food safety processes and it can be used in all areas of the food industry to aid continuous improvement & process optimisation, forecasting, the speed and accuracy of operations, and of course, productivity. A 2017 study by PWC found that global GDP will be 14% higher by 2030 as a result of AI adoption, which will contribute an additional $15.7 trillion to the global economy.

I believe AI will play an even bigger role in 2020. However, it can be really difficult for food manufacturers to know where to start. At OAL we help manufacturers to incorporate AI into their packaging lines to boost productivity by scanning over 1000 packs per minute inline much more accurately than human operators every could. Our AI-based label & verification systems also allow manufacturers to keep up with changing packaging formats without the need to re-programme the system – saving time and increasing throughputs. And because you have machine vision with a brain, you can switch to unmanned operations, further supporting your bottom line by reducing labour costs, all the while preventing product recalls and reducing waste. It’s a great first step for manufacturers looking to take advantage of the benefits of AI.

Are you ready to tackle your productivity challenge in 2020? Get in touch today to see where we can boost your production.

Spotlight on a career as Automation Development and Support Team Leader

Ethan Stone, 26, is an Automation Development and Support Team Leader at OAL. He lives in Alconbury with his fiancée.

Day in the life of…

Ethan Stone

Ethan Stone is an Automation Development and Support Team Leader at OAL. He lives in Alconbury.

My alarm goes off…

At 7.30am. I’m not a breakfast person so I generally get up and head straight for the shower to wake myself up. I then get dressed and try to wait for my partner to return from her night shift before I head off or sometimes I head straight into work.

I’m responsible for…

The day to day running of my department, which consists of myself and four other engineers. I lead the Factory Systems Automation team, and we are mainly responsible for the line management system (LMS), which is a production line automation solution providing performance monitoring to help increase efficiency within factories. I report to my manager with frequent updates on how we are doing to ensure we deliver the best for our customers. As the primary contact for the department both internally and externally I spend a lot of time speaking with current and prospective clients.

I got the job…

Based upon my previous experience working within automation in the oil and gas industry. I showed that I had a real passion for problem solving, which is ideal for OAL. I flourish in a setting that gives me autonomy to come up with practical solutions to hard technical problems – something I get to put into practice every day!

My typical day…

Could be anything! It could range from interpreting customer requirements and building a proposal for them or I could be working on any of the stages during our project lifecycle, from specification or development to testing and commissioning. Or I could be out and about supporting our customers with one of our existing systems. No two days are the same!

My most memorable moment…

Was graduating from my HNC in Electrical and Electronic Engineering. This was four years of education in parallel to working full time, including being on-call out of hours. It was hard work but it certainly paid off! I never saw myself wearing the gown and walking in a procession to celebrate my education in a cathedral but I’m so glad I did it.

The worst part of my job is…

That there sometimes aren’t enough hours in the day! It can feel like for every item I tick off my to do list, two more get added!

The best part of my job is…

Interacting with experienced engineers across a range of disciplines. From process engineers to plant operators – it’s a two-way conversation. Also, seeing something you’ve developed in action in real life; it’s really rewarding.

After work…

I drive home and cook dinner together with my fiancée. We then chill out and have some well-deserved rest and catch up with each other – I love finding out how her shift at the hospital was and what interesting patients she’s encountered.

Would you like to get involved in developing market-leading automation solutions? We are always on the look out for talented individuals, so get in touch to find our more!

Spotlight on a career as Installation Electrician

Will Woodham, 22, is an Installation Electrician at OAL. He lives in a small village outside Spalding.

Day in the life of…

Will Woodham

Will Woodham is an Installation Electrician at OAL. He lives in a small village outside Spalding.

My alarm goes off…

Usually in the early hours of the morning! The exact time depends on which site I’m working on, it could be anywhere in the U.K. and sometimes in Europe!

I’m responsible for…

Installing electrical systems for all of our solutions at our customers’ sites alongside my colleagues.

I got the job…

Originally through an apprenticeship scheme in 2014. My sister works for one of our customers, so she and gave me a list of companies that I might be interested in. Fortunately, OAL came back to me and the rest is history!

I originally worked as an apprentice electrician while studying at Peterborough Regional College to achieve my Level 3 NVQ Diploma in installing electrotechnical systems and equipment. Having finished my apprenticeship in 2018, I was promoted to become a fully qualified electrician, with greater responsibilities.

My typical day…

Can vary a lot, from working inside a factory, bakery or construction site to getting on top of silos and installing electrical systems and equipment. It keeps it interesting!

My most memorable moment…

Is always witnessing our systems go from drawings on a computer screen to fully functioning systems producing the food we buy in the supermarket.

The worst part of my job is…

The temperatures: the general rule is we’ll be working in hot bakeries in the middle of summer and working outside in the middle of winter!

The best part of my job is…

Being able to travel around the country and abroad!

After work…

When we’re away on site, we all usually go out together in the evening to a restaurant and have dinner, go back to the hotel, relax and watch TV.

Like the sound of what Will gets up to? As the winner of the SME Apprentice Employer of the Year 2019 in Peterborough, we’re always looking for apprentices to join the team!

Spotlight on a career as Assistant Management Accountant

Louise Gore is Assistant Management Accountant working within the Finance office. She lives in Huntingdon with her partner Neil and her son Owen.

Day in the life of…

Louise Gore

Louise Gore is Assistant Management Accountant working within the Finance office. She lives in Huntingdon with her partner Neil and her son Owen.

My alarm goes off…

At 6.30am and snoozed several times over! I then have a mad dash around the house to get ready and after several moans at my teenage son to get going, we’re both in the car and off by 8am.

I’m responsible for…

Many things finance related but over the past 6 months I have mainly been focusing on the looking after the company’s accounts to aid managerial planning and commercial decision-making, working closely with our Financial Controller.

I got the job…

Because I was in the right place, right time I believe. I had just been made redundant and saw the job advertised. I knew I was a good fit for the role, particularly with my existing qualifications so I was really pleased when I was offered the job!

My typical day…

Starts with going through any emails that have come through after I have left (I work part time). My work can change from day to day; I can be working with sales orders and chasing up timesheets to putting financial reports together for the management team to analyse departmental and overall performance.

My most memorable moment…

Can’t be pinned down to just one as I have had many in the finance office: contrary to popular belief finance is the place to be if you want to have good 'work-related' fun!

The worst part of my job is…

Filing…does anybody actually like it?!

The best part of my job is…

Working with such a knowledgeable team across the whole of OAL. Although I’m based in the finance office, I get to touch base with other departments throughout the week and see all the interesting things they are up to. It’s also great that we have so many training opportunities at OAL; I have started an apprenticeship to become ACCA qualified, which is really exciting!

After work…

If I’m not taxiing my son around to various places I like to relax with a good meal (generally made by Neil!) and maybe a glass of wine. The dog occasionally gets a walk too!

Looking for your next opportunity? We are always looking to grow the team with talented and ambitious individuals, so why not explore our careers to see what’s available!

Spotlight on a career as Project Coordinator

Sharon Proctor is a Project Coordinator working in the OAL Connected team at OAL. She lives in Peterborough with her husband Richard.

Day in the life of…

Sharon Proctor

Sharon Proctor, is an Project Coordinator working in the OAL Connected team at OAL. She lives in Peterborough with her husband Richard.

My alarm goes off…

At 6.30. We get up straight away as we have three cats who won’t let us sleep a moment longer when food is on the cards! I have breakfast with my husband and then get dressed and ready for work. Before leaving, I make us a packed lunch and then we hit the road for the short journey into work.

I’m responsible for…

Coordinating the administration for the OAL Connected team and their projects to ensure the smooth running of the whole department – I keep the team and our customers happy!

I got the job…

Originally around ten years ago. I started out as OAL’s receptionist and administration assistant, then progressing to office coordinator, a role I had for several years. Around two years ago I took on my current position in the OAL Connected team, having expressed an interest in moving into this department. When I moved to OAL Connected, I was amazed by how much I learned even though I had already been in the company for eight years!

My typical day…

Always starts by checking in with the team to make sure that everyone knows what each one of us is up to for the day; the guys are usually travelling all over the place visiting customers or carrying out support, so it’s a good way to start the day. I also double check that all arrangements have been made for those who are travelling so that no one is left stranded anywhere!

Then I start to work through ongoing projects, making sure that every aspect is accounted for to ensure accurate costs are logged and checking stock levels so that costs are controlled and we always have the right inventory for our customers.

My most memorable moment…

And the one that has had the most lasting impact on me is the fact that I met my now husband while working here! We met on my first day, had our first date a year later and then got married two years ago! (And we still work and live together very happily!)

The worst part of my job is…

Can be that we’re a team which is often subject to last minute changes! It keeps me on my toes at least!

The best part of my job is…

Getting to work with so many different people every day. The nature of the role means I need to work with every member of the OAL Connected team so it keeps my day interesting!

After work…

I like to go walking with my husband and we can usually be found hitting the pavements wherever we need to go (distance permitting!) We have also recently discovered our love of cruising as it’s a great way to explore many cities in one holiday so we always like to be planning our next adventure! And of course, we spend a lot of time pampering our three truly spoiled cats!

Interested in a career at OAL? We have a range of roles available and are always looking for talented individuals to join the team!

Spotlight on a career as a Senior Robotics Design Engineer

Michal Such, 32, is a Senior Robotics Design Engineer working in APRIL Robotics at OAL. He lives in Peterborough with his wife Joanna.

Day in the life of…

Michal Such

Michal Such is a Senior Robotics Design Engineer working in APRIL Robotics at OAL. He lives in Peterborough with his wife Joanna.

My alarm goes off…

At 6:30 am – I get up straight away and prepare breakfast and lunch. I leave home with my wife at 7:50 am and drop her off in the centre where she works, then drive to OAL.

I’m responsible for…

Designing our robotic systems. Most of my time is spent designing mechanical components, which includes fatigue analysis using Finite Element Analysis. We do a lot of robotic simulation that allows me to minimise the risks associated with automation. I also perform different robot studies and ensure that the cycle time complies with customer requirements and efficiency goals.

I got the job…

Thanks to my degree and experience in Automation and Robotics as well as good knowledge of the food industry. I wanted to continue my adventure in mechanical engineering and to find a company which combines automation and robotics within the food industry. Once I discovered what OAL can offer – developing innovative market solutions that nobody has yet designed – I knew that this was a company I wanted to work for!

My typical day…

Kicks off with a stand-up meeting with the entire team to sum up our progress. After that I grab a cup of coffee and go through my task list and emails. From there I get straight into the most important job I have for the day, which could be anything from designing new components, prototyping, simulation, testing or just supporting my team members.

My most memorable moment…

Is seeing a part that I have designed going into prototyping and then into final production – it never gets old!

The worst part of my job is…

Detailing components. Detailing is an integral part of a design engineer’s job and is the least interesting!

The best part of my job is…

Working on challenging tasks like designing something new and difficult. The more challenging the job, the greater the satisfaction, of course only if it has been done right.

After work…

I pick up my wife from work, drive home, we cook dinner together and chill out either by watching a film, working out or just spending time together.

Sound intriguing? We’re growing, and always on the look-out for talented and ambitious people. If you’re interested in a career at OAL, get in touch today.

Spotlight on a career as a Technical Trainer

A day in the life of Faye Louch, our OAL Connected Technical Trainer. She has over 20 years’ experience in a variety of technical and quality control roles within the food industry.

Day in the life of…

Faye Louch

Faye Louch is OAL Connected’s Technical Trainer. She has over 20 years’ experience in a variety of technical and quality control roles within the food industry.

My alarm goes off…

At 6am, although I am usually already awake thinking about the day ahead. I get up and have breakfast, and when I am at home, I say morning to the hubby and dog. Before leaving for work, I hide some treats around the house for the dog and put the radio on for him before setting off for another busy day at work. I will also usually give my son a quick call to check in with him and how he is getting on at uni.

I’m responsible for…

The training and health check audits of our label and date code verification systems in the field. The systems work by scanning every pack and comparing it to the pre-entered job information on the master database to make sure that the right packaging, label and date code is on the right product to prevent product recalls and emergency product withdrawals. The system can be perceived as quite complex, so my job is to train the users to make the most of it and ensure that we provide them with maximum protection.

I got the job…

After my son went off to university and I decided to take stock of what I wanted to do. While considering my options, I saw the job at OAL and applied. As I’m not an engineer, I didn’t think I would get it. However, OAL really valued my 20 years’ experience in the food industry, working in various roles from operator and section manager on production, to QA manager in a factory and technical system quality manager. I think it also helped that I enjoy systems and understand customer codes of practice (COP)!

I have to admit to being a little nervous when I first started at OAL but everyone is so friendly; it’s like a big family! We all pitch in and help each other, which is one of the things I love about working here.

My typical day…

Involves helping our customers to understand the information they input to the supervisory area of our system and how this data is translated and appears on the touchscreen that operators use on the factory floor. This screen offers all of the information they need and links to printers and scanners so they no longer need to set up printers by manually inputting the dates – this is where things can go wrong!

The other part of my job is visiting all of our sites that have our system and carrying out a health audit. This is like a check up on the system to ensure that it’s still functioning correctly post-installation. I also check it against OAL and customer COPs to ensure the system is compliant. If a COP has changed, I highlight any parts of the system that are no longer compliant so that fixes can be developed to ensure that the system is the best it can be for our customers. I also challenge test the system and look for ways to improve it.

My most memorable moment…

Was when we had the pleasure of BRC (British Retail Consortium) representatives visiting our facility to take them through our label and date code verification systems. After reviewing BRC COP issue 8, we had the pleasure of hosting them at our facilities to discuss their recommendations in detail, as well as practical applications. This helps our customers when it comes to audits going forward as the BRC representatives will understand our systems and interpret the standard reasonably.

The worst part of my job is…

Trying to keep on top of my emails, especially when I’m out on-site all day!

The best part of my job is…

That every day is different. I love working with our customers and seeing a job through from set-up to going live. Also, I love it when the operators I work with in the factory are a little reticent about the our systems, yet when you go back six months or a year later, those same operators take pride in it and train others on it – this really make it all worthwhile and is a pleasure to see.

After work…

I like to relax by going walking and once or twice a week I also go Taekwondo. My son is part of the GB Taekwondo Squad, and although he is away at university, I still spend a lot of time taking him training and competitions or train stations! Due to his passion for the sport, I agreed to take part with him rather than just watching. This means that now, I too love the sport and have achieved the level of black belt. I also took the Sports England Level 2 coaching qualification so I’m a qualified coach too!

Like the sound of what Faye gets up to? We’re always on the look-out for great talent and have a number of vacancies. If you’re interested in a career with OAL, get in touch today.

Spotlight on a career as a Product Development Chef

A day in the life of Chris Brooks 52, our Product Development Chef. He has over 35 years’ experience as a chef and has spent over 20 years in product development. He lives in East Northamptonshire.

Day in the life of…

Chris Brooks

Chris Brooks is OAL’s Product Development Chef. He has over 35 years’ experience as a chef and has spent over 20 years in product development. He lives in East Northamptonshire.

My alarm goes off…

At 5.30. I get up, walk the dog, have some breakfast and leave the house at 7.15 ready for another busy day.

I can be at the office in Cambridgeshire or working with the University of Lincoln at the National Centre for Food Manufacturing (NCFM), part of their Holbeach Campus. I also do quite a bit of travelling to customer sites all around the globe (in February it was Australia!) to help them make the most of our Steam Infusion technology.

I’m responsible for…

Supporting our customers with anything they may need to enable Steam Infusion to improve their end products. This involves both remotely connecting with the customer as well as spending time with them face to face, either at our test centre or at their site. Whether it’s the new product development team, the technical department or operations, I’m here to help them understand the technology and demonstrate how they can innovate with our systems. I assist in the writing of recipes, pushing the boundaries of taste and giving customers the confidence to utilise the science behind Steam Infusion to produce unique customer solutions.

I got the job…

Thanks to my in-depth knowledge of the food industry having worked with many major retailers along with household brands such as Saxby Bros, Hartley’s and Whitworths to name a few. I’ve also worked on products for celebrity chefs, such as Antony Worrall Thompson, Delia Smith and Mary Berry – so I have a good grasp of what both manufacturers and consumers are looking for. A well-rounded understanding of mechanical engineering and my experience as an army chef possibly helped too.

My typical day…

No day is the same as I could be doing any number of things. Often I’m working onsite anywhere around the world supporting customers in their tests or helping them to optimise their recipes for the technology. But I also have to spend time at the office working on recipes and formulations. The best thing about my job is there is no typical day!

My most memorable moment…

Of my time at OAL was definitely when we first cooked a sauce on the APRIL Robotic Chef. It really is a sight to be seen, especially how it pours rather than pumps the end product!

The worst part of my job is…

Knowing there is so much more Steam Infusion can do and not having the time to push the boundaries more. Oh, and the washing up after customers have left but even that isn’t too bad!

The best part of my job is…

Working with customers to help resolve any problems, watching their faces when they first see Steam Infusion and how quickly it works. I get to work with some fantastic people and I never stop learning.

After work…

I spend most evenings playing taxi to my son, taking him to his many clubs. I am a basketball referee, which I have my son to thank for as I wanted to get involved after spending so much time watching him play! I also support my local branch of The Royal British Legion where I have been their Standard Bearer for over 10 years helping to support our veterans and serving armed forces.

Fancy getting involved with projects with Chris? We’re growing and want to hear from enthusiastic and ambitious people. If you’d like to join the team, get in touch today.

Spotlight on a career in customer support

Latest in a new series from OAL, a day in the life of our fantastic employees. Joshua Pembery, 26, is a Trainee Customer Support Engineer at OAL Connected. He lives in March, Cambridgeshire.

Day in the life of…

Josh Pembery

Joshua Pembery is a Customer Support Engineer at OAL Connected. He lives in March, Cambridgeshire.

My alarm goes off…

At 6.30 – this gives me enough time to get up, get myself ready and leave the house for 7.30 ready to start another day at the office.

I’m responsible for…

Supporting our customers with any issues that they may have with their equipment. This involves both remotely connecting with the customer, whether it’s the engineering team, the technical department or operators themselves, to help them resolve any problems that have arisen on a line or visiting the site itself if they need a little more support and guidance. I’m also responsible for quoting and supplying spare parts and replacements to our customers. As this is a growing part of our business, I’ve recently taken on the responsibility of launching our e-commerce platform to offer customers a new way to purchase spare parts and training from OAL Connected. Customers expect to be able to deal with us online and we want to make it as easy as possible for them to get what they need to make the most of their systems - it’s been a great project to work on.

I got the job…

By taking a recommendation from a colleague of mine who had joined OAL. We had completed an apprenticeship at Nestlé together and it was there I gained my Level 3 in Proficiency in the Food Industry, which gave me knowledge and experience working in food. He had already made the move to OAL and was really positive about the culture and the values of the business, which did tempt me. At first, I wasn’t sure about the role, as the idea of a traditional customer service position didn’t really fit into my career plans. However, once I talked to OAL and explored the role further, I realised it there was so much more to the job and it would allow me to develop new skills and gain new experience so I’m really glad I pursued this career.

My typical day…

I get to work anywhere between 8:00am and 8:30am, depending on traffic. I make my morning cup of tea, check my emails for anything that’s come in overnight, and make my plan for the day ahead. Typically I could be doing anything from web development, to working with the support team, fixing things such as accessibility, as well as always being on standby for any queries that come in by email or phone from customers.

My most memorable moment…

Of my time at OAL so far is being asked to drive forward our e-commerce sales capabilities. It was great to be given so much responsibility and I realised that the company has real trust in me and was vested in my development. It’s great to work in a company that values its team.

The worst part of my job is…

Long distance drives travelling alone to customer sites – music only stays interesting for so long!

The best part of my job is…

Meeting customers, especially after speaking to them a lot on the phone – it’s always nice to put a face to a name and feel that you’ve made a real connection. I also love getting to work on projects by myself – it’s a great feeling of accomplishment when I complete them, and it helps me see how far I’ve come since I started.

After work…

I usually go home, have dinner and a shower and then do whatever I have planned for the evening, whether it’s going out to see a friend or family, or having a quiet night in playing some games.

Want to enjoy a similar day? We’re always on the look-out for great employees so get in touch today.

Double winners at MiCE awards 2019

We’re thrilled to announce that we were double winners at the Made in Central & East England (MiCE) Awards 2019! APRIL Eye took home the Digital Engineering/Technology Award and Kyle Constable, technical sales lead for Steam Infusion was recognised as the Apprentice of the Year. Following on from our regional win, we’ve now been entered into the national awards - keep your fingers crossed for us in June!

We’re thrilled to announce that we were double winners at the Made in Central & East England (MiCE) Awards 2019! APRIL™ Eye took home the Digital Engineering/Technology Award and Kyle Constable, technical sales lead for Steam Infusion was recognised as the Apprentice of the Year. Insider's MiCE Awards are a celebration of all that's great about manufacturing, shining a light on the region's innovations so we’re delighted to have been acknowledged - adding to our success at the end of 2018. Following on from our regional win, we’ve now been entered into the national awards - keep your fingers crossed for us in June!

All Eyes on APRIL™

APRIL™ Eye is the world’s first artificial intelligence vision solution and since its launch, it has been widely recognised as a game changer for the global food industry. The judging panel chose APRIL Eye as the winner of the Digital Engineering/Technology award for OAL’s desire to create jobs and export opportunities using this technology. It fully automates the date code verification process to reduce the risk of product recalls and withdrawals caused by human error on packaging lines. It’s great that MiCE also appreciates how APRIL Eye can make a significant improvement to processes, safety, quality and efficiency and deliver cost savings to food manufacturers on their packaging lines.

APRIL Eye transforms the traditional date code verification process by combining machine learning and artificial intelligence, fully automating the date code verification process. Rather than relying on operators to check the date code is printed correctly on every pack, APRIL Eye can remove the human error inherent in these boring, repetitive tasks by reading back the date code. The system can deal with variations such as lighting, positioning, print quality and placement to eliminate errors, protect consumers and the brand while at the same time reducing labour costs and waste.

High achiever

The MiCE Awards judging panel chose Kyle as their Apprentice of the Year for his "ongoing unwavering commitment to his personal development". We certainly agree with them!

Kyle Constable is a degree apprentice at OAL, helping UK and European food manufacturers adopt OAL’s Steam Infusion technology to ensure they maximise the benefits of the cooking process. With a strong background in the food industry having previously worked for Nestlé as a manufacturing apprentice, he is currently completing a degree in Food & Drink Manufacturing Operations Management at the University of Lincoln.

But Kyle doesn’t just take his own personal development seriously. As he represents a success story of taking an apprenticeship route to gaining a degree qualification within the food industry, he uses this experience to mentor students as part of the OAL CSR programme and takes every opportunity to encourage students to consider a career in engineering. It’s wonderful for Kyle to be recognised for such a prestigious award as it endorses his hard work combining studies with great results at the company.

We’re really making a difference at OAL. Want to join us on this journey? Get in touch to find out more about our award-winning solutions or if you want to be part of a team that values training and development, have a look at our careers page today.

SafeContractor accredited for fourth year running

We can announce that we have been approved as a SafeContractor for the fourth year in a row. Receiving the SafeContractor accreditation recognises our excellence in health and safety, both in terms of our workforce and our ways of working so you can be sure that you’re working with a responsible company.

We can announce that we have been approved as a SafeContractor for the fourth year in a row. Receiving the SafeContractor accreditation recognises our excellence in health and safety, both in terms of our workforce and our ways of working so you can be sure that you’re working with a responsible company.

Alcumus SafeContractor is a leading third-party health and safety assessment scheme. It helps to identify which companies meet the UK’s rigorous health and safety standards, offering an accredited contractor register to make it easier to find the right company to work with. Achieving the accreditation demonstrates that we’re taking responsibility for our legal health and safety requirements.

To gain the accreditation, we have proved that our health and safety paperwork is up to date and meets legal industry requirements. This includes a health and safety policy, risk assessments, COSHH assessments, construction phase plan, provision and use of work equipment and working at height.

Having the SafeContractor seal of approval means that you can be sure that we’re doing all we can to adhere to the very highest standard of health and safety and legal compliance and you don’t have to worry about our team carrying out work on your site.

Whatever your needs, you can be sure that we’ll do the best possible job for you. If you’ve got a project in the food industry, get in touch today and see how we can help you.

Harry Norman's predictions for 2019

Harry Norman, our founder, has his finger on the pulse. Constantly in contact with industry experts and customers, he makes it his job to find out what’s likely to affect our industry, and how we can help food manufacturers stay ahead of the curve. As the end of the year approaches, we spoke to Harry and asked him to share with us his take on the key trends to watch out for in 2019.

Harry Norman, our founder, has his finger on the pulse. Constantly in contact with industry experts and customers, he makes it his job to find out what’s likely to affect our industry, and how we can help food manufacturers stay ahead of the curve. As the end of the year approaches, we spoke to Harry and asked him to share with us his take on the key trends to watch out for in 2019.

Harry, take us through your top trends for food manufacturers in 2019.

I think there are three main areas that will influence the decisions of food manufacturers in 2019. These are labour costs or labour shortages, allergen control and health & safety

Let’s start with the issue of labour. Is this just something that is affecting the UK?

The number one thing that everyone is going to be talking about in 2019 is the cost of labour and labour shortages. At every show we attended in 2018, it was clear that this is something that is starting to weigh heavily on many manufacturers’ minds. That’s not just the case in the UK, where wages are rising and labour is in short supply due to the upcoming Brexit deal, but also across Europe and the rest of the world. In addition, initiatives like the living wage mean that our operators are getting paid better, but that can then eat into your margins.

Having the option to reduce your workforce, or at least better deploy operators into more value-adding roles, is going to become a priority for many food producers who may struggle to stay in business without the possibility of mitigating wage increases or labour shortages.

And management of allergens, have we not got this under control already?

Unfortunately, we saw in 2018 what happens when allergen controls go wrong. With the inclusion of sesame flour without clear labelling, a child lost her life. Now, we all know that it was an unintended consequence of the retailer’s operations, but it shouldn’t even be a possibility. As consumers, we all like to think that manufacturers have it taken care of but many existing operations don’t easily lend themselves to full allergen control.

We need to get to a point where there is absolutely zero cross-contamination in our processes so that whatever allergy someone has, there is no risk of coming into contact with that food stuff. Obviously the number one priority is consumer safety, but food manufacturers also have to think of the financial consequences and brand damage that can occur when they get it wrong, and consider their options so that they can achieve full allergen control in their facilities.

Why do you see health & safety as such a big issue in the food industry?

Health & safety is a concern for any industry, but the food industry is a particular hotspot for these sorts of issues. From musculoskeletal disorders caused by operators carrying sacks of ingredients, to cases of asthma and rhinitis from working with powders, food manufacturing facilities can cause a multitude of health problems for those on the factory floor. The Health & Safety Executive (HSE) in the UK, and similar bodies globally, are aware of this and are looking to crack down to protect workers.

Let’s take the issue of powders. In the UK, the HSE requires bakeries to avoid exposing its employees to flour dust, or where not practical, to adequately control exposure. The Workplace Exposure Limit (WEL) of flour dust is 10mg/m3 (averaged over 8 hours) for long-term exposure and 30mg/m3 (averaged over 15 minutes) for short-term exposure. Yet the HSE believes that 2mg/m3 flour dust in the air for staff working in the weighing and handling of powder ingredients is possible to achieve.* Many bakeries, and other food facilities, will wonder how that could be possible with their existing equipment, but it’s something that they’re going to have to solve in the next year or so. As we saw in early December, the HSE has issued a £150,000 fine to a bakery that didn’t do enough to protect its operators - it’s a good idea to review your operations before it happens to your plant.

While seemingly insurmountable challenges, there are technological solutions to help you overcome them. So why don’t you make it your New Year’s resolution to dip your toe in the water and start to apply machine learning or robotics to a simple problem in your business? It’s easy to start your digital transformation journey and unlock the benefits of automation with a partner like OAL.

APRIL™ Eye wins Food Processing award

We’re delighted to reveal that our APRIL Eye innovation has received yet more industry recognition in the form of the award for Robotics & Automation at the 2018 Food Processing awards. APRIL Eye is the world’s first artificial intelligence vision solution, which fully automates the date code verification process to eliminate the risk of product recalls and withdrawals caused by human error on packaging lines.

We’re delighted to reveal that our APRIL™ Eye innovation has received yet more industry recognition in the form of the award for Robotics & Automation at the 2018 Food Processing awards. APRIL™ Eye is the world’s first artificial intelligence vision solution, which fully automates the date code verification process to eliminate the risk of product recalls and withdrawals caused by human error on packaging lines. This is yet more good news for our customers and the OAL Connected team following on from the PPMA award win in September 2018.

The Food Processing Awards take place annually to recognise and reward engineering innovations in the food and beverage sector. Beating off stiff competition to be nominated as a finalist, it’s a great achievement for us to take home the prize in this thriving category and clearly demonstrates the industry’s confidence in the impact our APRIL™ Eye technology can make on the food manufacturing industry.

Combining artificial intelligence with machine vision, APRIL™ Eye revolutionises the traditional date code verification process. Food manufacturers no longer need to rely on operators to check if the date code is printed correctly as APRIL™ Eye fully automates the verification process and removes human error from these boring, repetitive tasks. The system reads back the date code seamlessly and can deal with variations such as lighting, positioning, print quality and placement to eliminate errors. The system offers significant improvement to processes, safety, quality and efficiency as well achieving cost savings for food manufacturers on their packaging lines.

Harry Norman, OAL Managing Director, comments, “It’s another great achievement for us to win the Food Processing award for our APRIL™ Eye date code verification system. APRIL™ Eye was developed as part of our Food Manufacturing Digitalisation Strategy, supported by the University of Lincoln and Innovate UK grant funding, and designed to investigate how artificial intelligence could revolutionise this key area of the food manufacturing process. It’s wonderful to receive this industry recognition and clearly demonstrates how successfully we have met our objective to bring a multitude of benefits to our customers through automation.”

So if you’re interested in our multi-award-winning innovation, please get in touch to find out how we can transform your end of line verification process.

Double win for OAL at PPMA 2018

We’re very proud to announce that we took home two accolades at the PPMA Awards 2018. Our APRIL Eye system won the Innovative Vision Solution award, while Kyle Constable, Steam Infusion technical sales lead at OAL, was named Apprentice of the Year.

Innovative Vision Solution Award & Apprentice of the Year

PPMA awards

We’re very proud to announce that we took home two accolades at the PPMA Awards 2018. Our APRIL™ Eye system won the Innovative Vision Solution award, while Kyle Constable, Steam Infusion technical sales lead at OAL, was named Apprentice of the Year. We were also highly commended for our APRIL™ Robotics Ingredient Handling system! The awards recognise the finest examples of innovation, smart manufacturing and entrepreneurship in the UK food industry, and we’re delighted to have been acknowledged in three categories.

Eyes on the prize

APRIL™ Eye is the world’s first artificial intelligence vision solution. It fully automates the date code verification process to reduce the risk of product recalls and withdrawals caused by human error on packaging lines. The Innovative Vision Solution award celebrates equipment suppliers, system integrators or end users who have manufactured, designed or installed a clever, creative or innovative industrial solution. It’s fantastic that the PPMA appreciates how APRIL™ Eye can make a significant improvement to processes, safety, quality and efficiency and deliver cost savings to food manufacturers on their packaging lines.

By combining machine learning and artificial intelligence, APRIL™ Eye transforms the traditional date code verification process, which relies on operators to check the date code is printed correctly. APRIL™ Eye removes the human error inherent in these boring, repetitive tasks by reading back the date code, fully automating the date code verification process. The system can deal with variations such as lighting, positioning, print quality and placement to eliminate errors, protect consumers and the brand while at the same time reducing labour costs and waste - it’s the full package!

“You’re hired”

Acknowledging emerging talent within the food industry, the Apprentice of the Year award celebrates the most promising apprentice, and in particular their future leadership potential. Kyle Constable is a degree apprentice at OAL, helping UK and European food manufacturers adopt OAL’s Steam Infusion technology to ensure they maximise the benefits of the cooking process. With a strong background in the food industry having previously worked for Nestlé as a manufacturing apprentice, he is currently completing a degree in Food & Drink Manufacturing Operations Management at the University of Lincoln.

The award is designed to encourage more young people to take up careers in the industry, a cause that Kyle takes very seriously as he represents a success story of taking an apprenticeship route to gaining a degree qualification within the food industry and uses this experience to mentor students as part of the OAL CSR programme. It’s wonderful for Kyle to be recognised for such a prestigious award as it endorses his hard work combining studies with great performance at the company.

Harry Norman, owner of OAL, comments, “A double win at the PPMA awards - who could ask for more? We’re absolutely thrilled to win the Innovative Vision Solution PPMA Award and for Kyle to be recognised as the Apprentice of the Year. It really demonstrates to our peers the significance of the work that we’re doing and celebrates one of our team members and the valuable contribution that he makes, not just to our company but the industry as a whole.”

We’re really making a difference at OAL. Want to join us on this journey? Get in touch to find out more about our award-winning solutions or if you want to be part of a team that values training and development, have a look at our careers page today.

OAL speaking & exhibiting at the Smart Food Factory Summit

We're very excited to be speaking and exhibiting at Food & Drink Business Europe's Smart Factory Summit 2017. The event is taking place on Tuesday 7 November 2017 at the Ricoh Arena, Coventry and aims to bring together professionals from the UK's food and beverage industry to facilitate knowledge, sharing and collaboration.

Jake Norman, Head of Innovation at OAL will be speaking about how OAL are putting robotics and automation at the heart of food processing with our APRIL™ Robotics solutions. Hear how we have invested, researched and developed the very latest in advanced robotics and automation technology to help food manufacturers solve challenges driven by the increasing living wage, flat line productivity and food deflation.

Alongside Jake Norman's talk, visit our stand to see how we're using £4 million of Innovate UK research projects to bring about a step change in food manufacturing using technologies including collaborative robotics, advanced vision, machine learning and big data to tackle your productivity, food safety and traceability in your food factory.

Discover how you can turbocharge your cooking process with OAL's Steam Infusion heating and mixing technology scientifically proven to help food manufacturers overcome slow cooking times, burn on contamination and over-processing. How else can you cook 500kg of sauce in just 5 minutes?

Our experts will also be on hand to share best practice advice around stopping label and date code errors and retailer code of practice compliance with our IoT based software OAL Connected. Whilst you're on our stand, make sure you pick up our latest brochure discussing the five best practice steps for continuous improvement in food manufacturing and see how easily you can implement them into your factory.

So with lots to learn, see and discover, sign up today to join us at the Food & Drink Business Europe Smart Factory Summit 2017. We can't wait to meet and discuss how powerful new digital technologies can impact your food business and start you on your journey towards automation!

OAL leads research project into cryogenic cooling

We’re pleased to announce the launch of our latest research project set to revolutionise ready meals with cryogenic cooling in partnership with BOC, The University of Lincoln and Iceland Manufacturing. The £969,000 project, part funded by Innovate UK will last two years and aims to develop an innovative cooking and cryogenic cooling system for ready meals providing a step change in product quality and healthiness. The project seeks to help tackle the current levels of food waste and increase the speed of production.

The project will combine our rapid cooking Steam Infusion Vaction™ technology with a cryogenic cooler from BOC. It follows our first major Innovate UK project ‘Nutrition for Life’, that has focused on understanding the full operating envelope of our Steam Infusion cooking technology and it's effects on nutrition and food safety.

Over the two-year project, the team plans to gain a full scientific understanding of the effects of rapid cooling using liquid nitrogen on sauces and soups, and the vegetables, fruits and meats they contain in order to maximise nutritional values. Product shelf life could also be increased and waste minimised as we will develop a fully flexible process that will reduce production, cleaning and changeover times for increasingly variable supply requirements.

Food is Life at Gulfood Manufacturing "Food Wall"

At Gulfood Manufacturing, Dubai, the biggest food show in Africa and the Middle East, we decided to do something different to engage visitors. Steam Infusion is a revolutionary heating and mixing process, and from previous shows in the UK we recognised we need food manufacturers to think creatively and differently about their manufacturing processes. So to break down barriers and to get people thinking about what’s really important about food, we introduced them to our “food wall”. Visitors were simply asked to write what was most important about food to them on our “food wall”.

We were genuinely amazed by the excitement and engagement with the "food wall". Over the 3 days of the show, 473 people signed the wall from 70 different countries. Writing in Arabic, Chinese, English, Filipino, Hebrew, Japanese, Swahili, and Turkish to name a few. It really was a truly eclectic mix of global opinions on what’s important about food.

What we found?

Coming from the UK we were expecting people to write the commonly accepted important factors of food such as safety, quality, taste and flavour. These were key elements and many people from all over the world cited safety and taste as the most important areas to them.

But interestingly there was a real focus on the fundamental link between food and life. For instance “Food is life itself”, “Can’t live without food”, and “Africa needs more food.”

But should we have been surprised? Nestle, the biggest food manufacturer in the world, has the slogan “Good Food, Good Life,” clearly linking food to life itself and it’s true to say that without food we wouldn’t be here. But on a daily basis as engineers and food manufacturers do we make the connection between food and life in the UK?

But what’s the link with Steam Infusion?

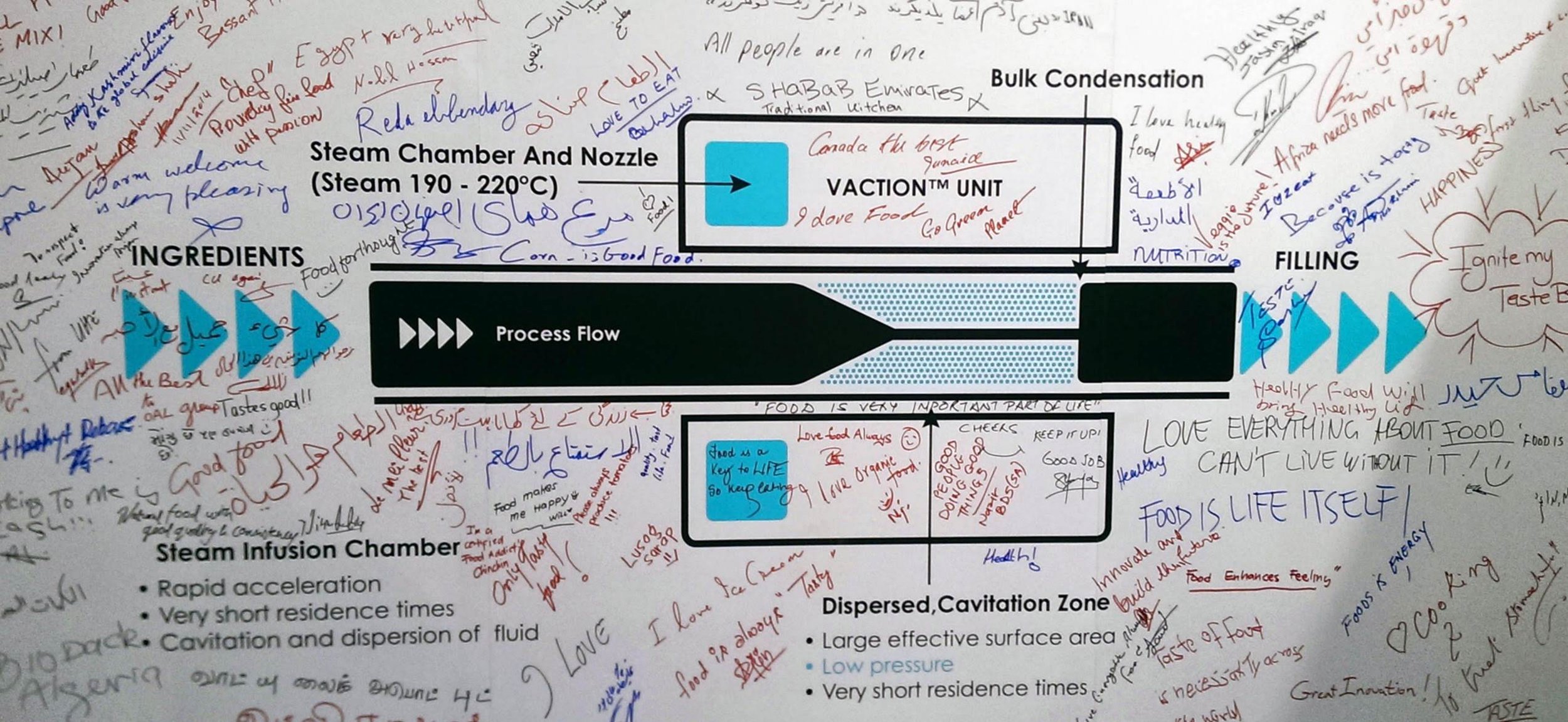

Gulfood Food Wall Steam Infusion Unit

Often at exhibitions visitors have very specific requirements about what they are looking for and to a certain extent are closed down to things outside of their remit. By simply asking visitors to write what’s important about food on the wall, we found visitors opened up much more and were in a much better position to discuss innovation.

This innovation mind-set is really important to us because often with the Steam Infusion process we are radically changing traditional manufacturing processes, for instance going from a multi stage process to a single stage faster process. Likewise we found visitors engaged much more strongly with new product development and step changes to improving flavours and taste having written on the wall.

Hot application at Gulfood

Food is Life Gulfood Manufacturing Steam Infusion

Not only were people able to write on our walls but they could taste the difference as well. On the stand, we had pots of freshly made condensed milk made using Steam Infusion which attracted a lot of interest because of the considerable difference in product quality and operational performance. Steam Infusion condensed milk suffers no burn on discolouration, has a particularly smooth texture and cuts manufacturing times by 50%.

Super Steam Infusion Autumn: 9 innovation events, 6 awards

PPMA Innovation Award Steam Infusion

It’s been a busy September for the OAL team! Off the back of winning an award for Steam Infusion at the European Food Venture Forum in Denmark, we were at Leatherhead Food Innovation Day presenting Steam Infusion followed by the FDF Awards. With lots more events on the horizon, here are the highlights!

Steam Infusion won the most innovative food processing or packaging machine award at the PPMA Group Industry Awards 2014, held at the National Motorcycle Museum, Tuesday 30 September. In a very competitive category, Steam Infusion was recognised as the most innovative technology by the esteemed judging panel because of the health benefits the technology can bring to the food industry.

Steam Infusion EFVF2014AwardWinners

The European Food Venture Forum saw OAL pitching Steam Infusion's ability to create exciting new food products and ingredients to investors and manufacturers. The judging panel included senior executives from Anterra Capital, Arla Foods, BASF Venture Capital GMBH and Dupont Nutrition & Health all of whom assessed the technology on its business potential, technological merit, competitive position, and investment interest and team experience. Strong engagement from the judging panel and an award to go with it was a fantastic endorsement of the technology’s unique processing environment.

Leatherhead’s annual Food Innovation day seeks to showcase exciting technology developments within the food industry. Steam Infusion was well received by executives from 2 Sisters Food Group and Mondelez International particularly around the technologies ability to process heat sensitive food materials.

The very same evening saw the Food & Drinks Federation Awards, where Steam Infusion came runner up in the Innovation category.

Look out for us in the news as we have been shortlisted for more awards:

Ben Bowman

One of our talented engineers, Ben Bowman, is shortlisted for the young talent of the year category at the Food Manufacture Awards.

OAL has been shortlisted for company of the year and technological development at the Food Processing Awards 2014, please vote for us on their website.

Jake Norman, Sales & Marketing Manager, has been shortlisted for the 2 Degrees network Top 25 Under 25 year-olds in sustainability.

With a busy autumn ahead, you can meet the team at the following events:

OAL are sponsoring and will be attending Appetite For Engineering 2014, 21st October. We have a number of complimentary tickets available, please contact us if you are interested in attending, Tuesday 30th September to Thursday 2nd October.

Jake Norman (Sales & Marketing Manager) is speaking at Pack Expo in Chicago on the General Electric stand about Steam Infusion, sharing how we use GE connected insights for R&D into creating new and unique food products and ingredients.

OAL will be presenting at the prestigious Innovate UK Event 2014 “The Global Spotlight on UK Innovation”, 5th & 6th November, Old Billingsgate, London, find out more here.

The team will be at Gulfood Manufacturing, Dubai from 9th to 11th November presenting Steam Infusion, register here.

Winning at the European Food Venture Forum means the team progress to the final of the European Venture Contest in Dusseldorf, Germany, taking place 8-9th December 2014. Find out more here.

Steam Infusion shortlisted for FDF Innovation award

Steam Infusion from Olympus Automation (OAL) has been shortlisted for the Food and Drink Federation (FDF) Innovation Award based on its ability to deliver significant and innovative change to the food industry.

Steam Infusion is a revolutionary heating and mixing process that uniquely infuses steam into liquid food products in a vacuum. Early adopters of Steam Infusion include Greencore and Larco Foods who have generated significant business benefits from the technology. explains,

“Steam Infusion has allowed us to nearly double our previous throughput rates in sauce production. On top of this our meat sauce quality and consistency has improved dramatically.”

Further research and development is being undertaken in a £1 million UK government funded Nutrition for Life project at the Steam Infusion Test Centre in the National Centre for Food Manufacturing, Holbeach.

The unique Steam Infusion environment has been found to increase the flavour profile of food products in commercial trials indicating salt and other ingredients can be reduced without having a negative impact on flavour. The Nutrition for Life project seeks to provide the scientific understanding of the level and nature of the changes brought about by the steam infusion process and the nutritional advantage to be gained.

OAL will be presenting initial findings from the Nutrition for Life project at the PPMA show 2014 running from 30th September to 2nd October 2014. As well as the OAL team, academics from the University of Lincoln will be on the stand to answer questions on Steam Infusion and the project.